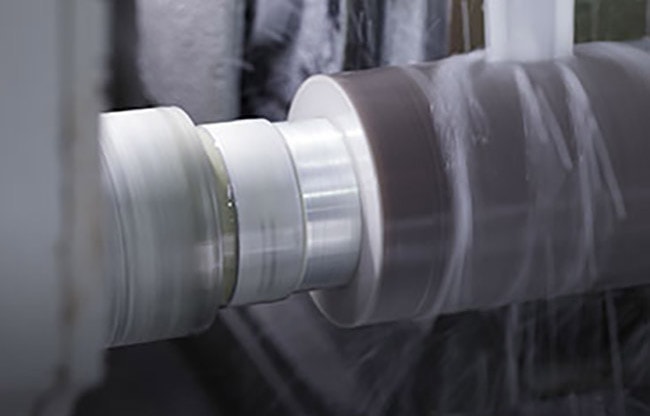

Computer numerical control (CNC) machining has significantly grown in popularity for producing glass components with complex geometries. At Swift Glass, we specialize in glass CNC machining using the most advanced machinery. Our state-of-the-art diamond tooling technology allows us to handle the toughest materials with optimal precision and accuracy. With the ability to process glass components in a variety of sizes and thicknesses, Swift Glass is one of the most versatile, reliable manufacturers worldwide.

Premium Glass CNC Machining at Swift Glass

Swift Glass is a leader in premium glass CNC machining. We are your one-stop shop, specializing in creating the glass components you need with cutting-edge technology and expert craftsmanship. Our glass CNC machining capabilities include:

- Diamond Tooling Expertise. Our 3- and 4-axis diamond tooling technology can handle even the most challenging materials, such as Schott BOROFLOAT® Glass high-pressure gauge glass, quartz, and other glass materials.

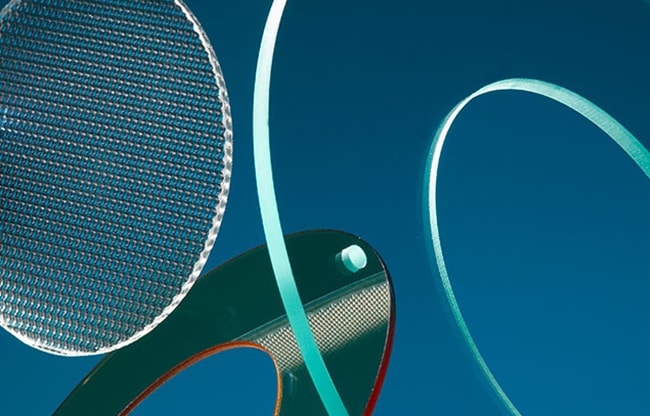

- Wide Size Range. We can handle projects of all sizes, with the ability to process materials up to 27 by 48 inches and thicknesses up to 8 inches.

- Unparalleled Material Selection. We carry a range of quality glass materials from leading manufacturers. Browse our materials to determine the ideal glass material for your specific project.

- Profile-Forming Services. Ideal for specialty projects, our profile-forming capabilities can bring unique designs to life.

- Unmatched Production Capacity. Our advanced facility can handle single prototypes to high volumes exceeding 100,000 units.

Our broad range of premium CNC glass machining services includes:

- Boring

- Drilling

- Engraving

- Grooving

- Pocketing

- Slotting

- Surfacing

Is CNC Glass Machining Right for Your Application? Main Benefits

Selecting the ideal fabrication method is essential to ensuring the success of your glass project. Compared to traditional forming and glass cutting techniques, CNC glass machining offers several advantages that can improve your project overall. Some of the primary benefits of CNC glass machining include:

- Enhanced Material Versatility

- Unmatched Precision and Accuracy

- High Efficiency and Speed

- Improved Design Freedom

- Increased Project Scalability

- Superior Strength and Integrity

When your project demands high precision, specialized materials, and complex designs, CNC glass machining is the ideal solution. Offering enhanced efficiency and versatility, glass CNC machining ensures you get the exact glass components you need.

Industries Served

At Swift Glass, we provide glass milling solutions for a range of commercial, industrial, and residential arenas. Some of the industries that we serve are:

- Optical

- Lighting

- Industrial

- Marine

- Automotive

- Aerospace

- Energy

- Building

- Architecture

- Medical

- Petrochemical

- Semiconductor

- Government and Military

Quality You Can Trust – The Swift Glass Advantage

Swift Glass has been a leader in dependable, high-quality glass fabrication services for nearly a century. We are committed to delivering:

- High-Accuracy Results. We can machine glass materials with superior precision, delivering products that exceed client expectations.

- Short Lead Times. Our efficient processes ensure we can meet your project deadlines.

- Quality Service. We strive to provide first-rate customer service from start to finish.

- Industry Expertise. Our in-depth knowledge and vast experience allow us to deliver solutions for the most challenging projects. We maintain an ITAR registration and ISO 9001:2015 certified quality management system.

Ready to Bring Your Glass CNC Machining Vision to Life? Contact Our Experts Today!

CNC machining offers a highly precise and accurate method for fabricating complex glass components. At Swift Glass, we provide superior glass CNC machining services that meet our clients’ exact specifications and standards. For more information about our glass CNC machining capabilities, or to get started on your custom solution, contact us or request a quote today.