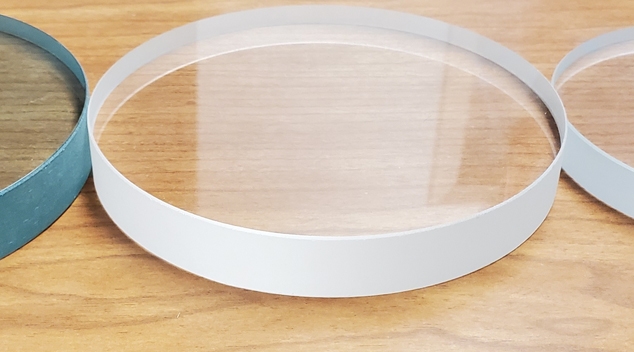

At Swift Glass, we fabricate custom glass wafers that adhere to the high standards of the semiconductor industry. Our glass wafers can be used as temporary or permanent semiconductor materials. Glass wafers used for semiconductors are thin, precision-fabricated glass discs made of fused silica, quartz, or borosilicate glass and act as carriers for Micro Electro Mechanical Systems (MEMs) substrates like silicon.

Understanding the material options and capabilities used to fabricate glass wafers will help you determine the ideal solution for your semiconductor application.

Semiconductor Glass Fabrication Solutions From Swift Glass

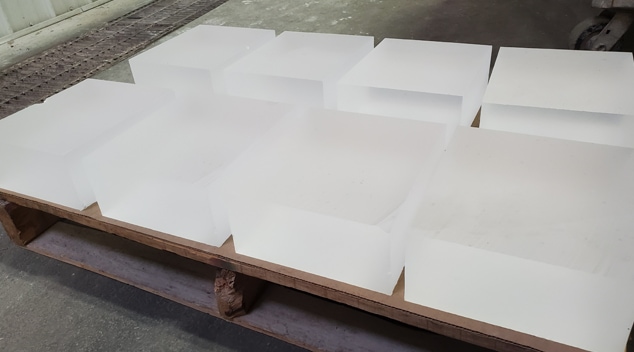

Swift Glass has a prototype and specialty production shop that handles small to large production runs, with a minimum production run of one unit. We can scale our operations based on your fabrication needs and use advanced systems to cut wafers of various materials with thicknesses as small as 0.3 mm. When you trust Swift Glass with your glass wafer manufacturing needs, you benefit from high-quality fabrication materials, sophisticated cutting tools, finishing machines, and our industry-leading experience.

Benefits of Using Glass in Semiconductor Applications

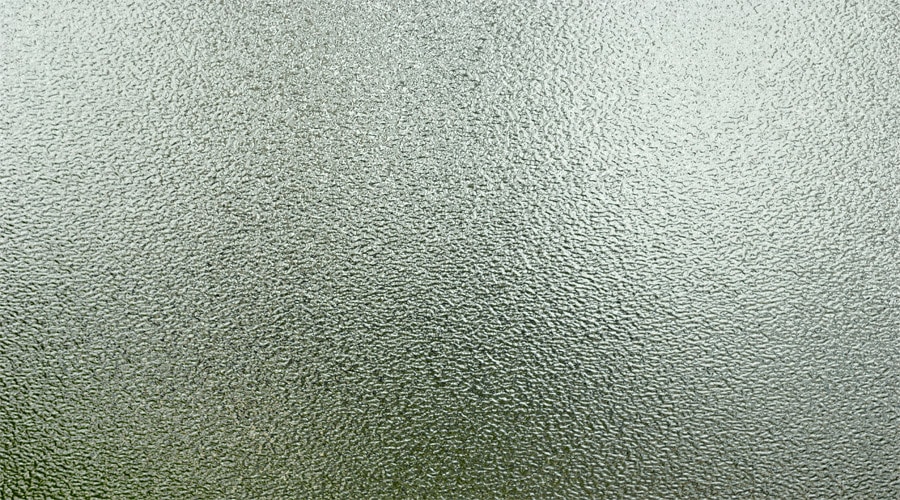

Glass, which can be customized to meet the unique needs of customers, has many benefits for semiconductor applications. Due to its transparency, glass facilitates laser debonding. Other advantages the material offers over conventional silicon wafers include lower cost, less electrical loss, thermal stability, reduced thermal expansion, and greater stiffness to reduce warping. Glass wafers can be safely handled despite their slim size and fragility. Because of these traits, glass is ideal for semiconductor manufacturing.

Glass Materials for Semiconductor Manufacturing

Swift Glass uses the following materials in our semiconductor glass fabrication projects:

- Borosilicate: Borosilicate offers exceptional thermal stability, making it ideal for high-quality, heat-tolerant glass parts. It is composed of high concentrations of boron trioxide and silica and offers resistance to thermal shock.

- Corning Eagle XG®: Corning’s Eagle XG® slim glass substrate has a coefficient expansion similar to silicon, making it ideal for semiconductor applications. This glass is exceptionally thin and contains no heavy metal additives, which reduces the environmental and adverse health effects of fabricating the glass.

- Schott BOROFLOAT® Glass: Schott BOROFLOAT® Glass is a cutting-edge material that offers toughness, chemical resistance, and thermal resistance in a lightweight, transparent package. Its versatility makes it suitable for many applications, including semiconductor manufacturing.

- Quartz/Fused Silica: Quartz is a high-purity material that withstands the pressures and high temperatures associated with manufacturing semiconductors. Fused silica is also ideal for its near-zero thermal expansion, UV transparency, and shock resistance.

Custom Glass Fabrication Solutions

At Swift Glass, we work closely with our clients to develop and customize their glass wafer semiconductor fabrications. Our expert team will fabricate your custom design and ensure it is perfect. We take pride in our ability to meet the demands of every project, regardless of design complexity or size.

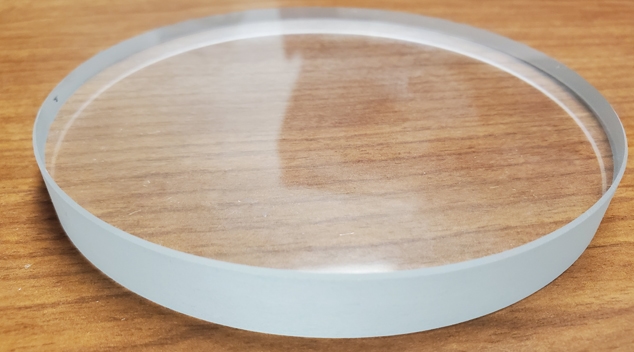

Glass Wafer Specifications

Our glass wafer fabrication capabilities can accommodate various flatness, thickness, surface quality, and edge profile specifications. We offer the following specifications:

| For diameter measurements <200 mm |

For diameter measurements >200mm | For Diameter measurements: >200mm but <450mm | |

|---|---|---|---|

| Thickness: | .3mm | .3mm to 10mm | .55mm to 10mm |

| Capabilities: | +/- 25µm | +/- 25µm | +/- 25µm |

| Total Thickness Variation (TTV): | <3µm | <3µm | <3µm |

| Surface Roughness (Root Mean Square) Average: | <12Â | <12Â | <12Â |

| Scratch Dig: | 40/20 | 40/20 | 40/20 |

| Bow: | <58µm | <58µm | <58µm |

| Warp: | <10µm | <10µm | <10µm |

| Flatness: | <1µm |

Contact Our Experts for Premium Semiconductor Glass Fabrication Solutions

Glass wafers protect the semiconductor and facilitate operation as a substrate carrier. Swift Glass fabricates glass wafers for semiconductor applications, with the capability to produce low to high volumes of glass wafers in thicknesses as thin as 0.3 mm. Precision-fabricated glass wafers improve semiconductor manufacturing and function by increasing stiffness and protecting the semiconductor from warping and heat. Swift Glass fabricates glass wafers from borosilicate, quartz, fused silica, Corning Eagle XG®, and Schott BOROFLOAT® Glass. We fabricate customer designs and can ensure your semiconductor glass fabrication solution meets your expectations by offering a range of customizable specifications.

Swift Glass is an ITAR- and ISO 9001:2015-certified manufacturer that has been delivering quality custom-fabricated glass components for nearly a century. Trust our experience in serving the semiconductor wafer market. Contact us or request a quote to connect with a member of our team about the semiconductor glass fabrication solution for your application.