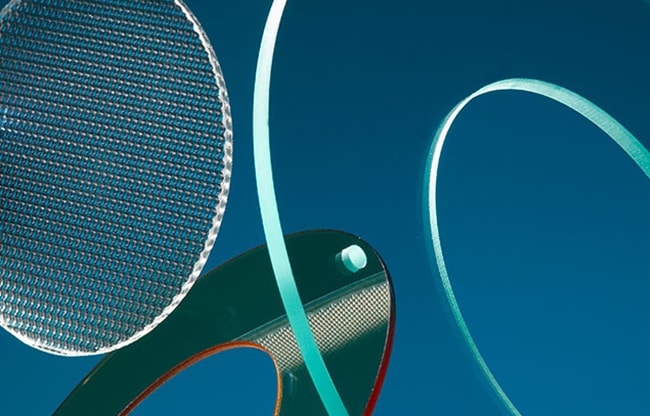

As a worldwide leader in the manufacture of quality fabricated glass parts, Swift Glass has years of experience fabricating sight glass for many applications. To help make the process of selecting your sight glass disc even easier, we’ve created a glass-thickness calculator that you can use below.

Simply type in the unsupported diameter of the glass you’re working with, as well as the PSI it needs to withstand, and it will provide the recommended thickness to ensure optimal strength and durability. If you already have the unsupported diameter and the thickness of the piece of glass you will be working with, you can enter those values and calculate the PSI that it will be able to withstand.

Select Your Glass Material

- Borosilicate (Annealed)

I Want to DetermineNecessary

Glass ThicknessCalculate!Max. Working Pressure to Withstand

(15 - 400 psi)Unsupported Diameter

OrI Want to DetermineMaximum Working

Pressure it Can WithstandCalculate!Thickness

Unsupported Diameter

- Borosilicate (Tempered)

I Want to DetermineNecessary

Glass ThicknessCalculate!Max. Working Pressure to Withstand

(15 - 400 psi)Unsupported Diameter

OrI Want to DetermineMaximum Working

Pressure it Can WithstandCalculate!Thickness

Unsupported Diameter

- Soda Lime (Annealed)

I Want to DetermineNecessary

Glass ThicknessCalculate!Max. Working Pressure to Withstand

(15 - 400 psi)Unsupported Diameter

OrI Want to DetermineMaximum Working

Pressure it Can WithstandCalculate!Thickness

Unsupported Diameter

- Soda Lime (Tempered)

I Want to DetermineNecessary

Glass ThicknessCalculate!Max. Working Pressure to Withstand

(15 - 400 psi)Unsupported Diameter

OrI Want to DetermineMaximum Working

Pressure it Can WithstandCalculate!Thickness

Unsupported Diameter

Please note that we provide this calculator as a tool for your estimation to use with no expressed or implied warranties regarding the results. While we have made every effort to assure the accuracy of the calculations, Swift Glass Company will not be held responsible for the results or any subsequent problems that may occur as the result of the use of the information contained herein. Swift Glass Company excels at manufacturing products to customer specifications and does not provide any engineering or design services. If you are unsure of the design requirements for your application consult an engineer. Considerations of the environment, (including temperature,) the sight glass will be used in, the chemical and mechanical properties of the material selected and the desired safety factor needed must be made. In pressure situations, proper gasketing and proper mounting are required to absorb irregularities of the housing. Swift Glass Company recommends all sight glass be examined periodically for scratches, etchings and other defects. All defective parts should be replaced.