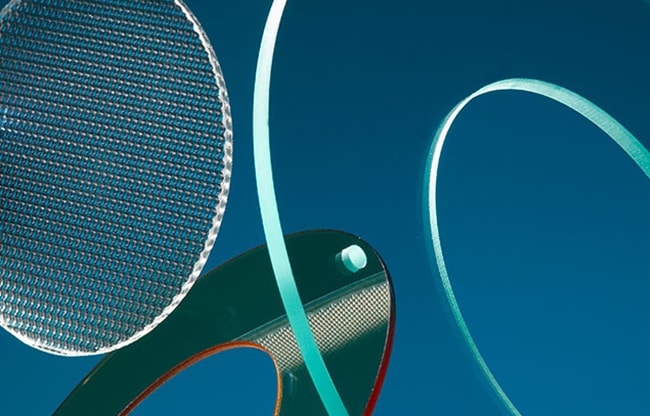

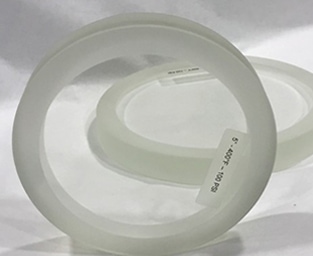

Annular edge glass is a transparent, high-pressure resistant glass composed of borosilicate with sandblasted edges to fit a variety of industries. It is a one-of-a-kind edge glass that provides superb transmission over the full light spectrum. Other features to annular edge glass include:

- High thermal resistance

- High chemical durability

- Excellent mechanical strength

Currently, Swift Glass is the only glass manufacturing company that offers specialized annular edge glass products. Here, we share how we craft this unique product and how it can serve your business.

How Is Annular Edge Glass Crafted?

At Swift Glass, we construct our annular edge glass from SCHOTT BOROFLOAT® glass. BOROFLOAT® is a high quality borosilicate glass. BOROFLOAT® is versatile and has many features that differentiate it from other glass materials on the market.

These include:

- Exceptional visual quality and optical clarity

- High thermal stability

- High resistance to marks or scratches

- Resistant to acids, alkalis, and hydrolysis

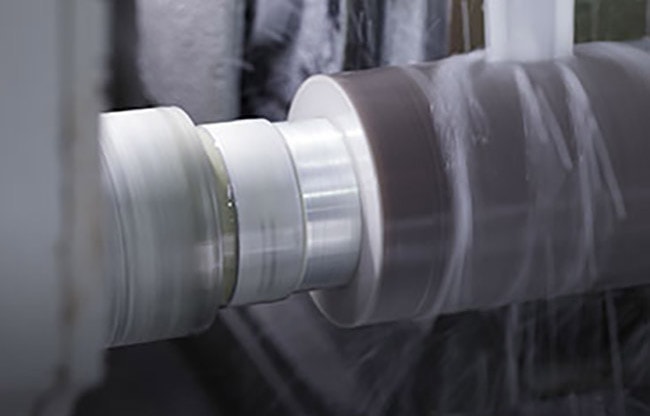

To begin the manufacturing process, we cut strips of glass. The glass then gets blasted by a waterjet cutter then refined through an OD grinder to get the specific shape and size. Next, we chamfer and bevel the glass to remove any sharp edges or inconsistencies, ensuring the glass is smooth, uniform, and in optimal condition. Once the glass is fit for the final product, we sandblast the glass, load them into a washer, and provide a thorough cleaning. Once cleansed, the annular edge glass is inspected for quality. After the glass passes the final inspection, the manufacturing process is complete, and the order is ready for shipment.

Applications of Annular Edge Glass

Due to the affordability and inherent properties of annular edge glass, it is a versatile specialty glass material that serves a multitude of businesses.

We offer two different types of annular edge glass, suitable for any high-pressure or low-pressure application.

- Standard Annular Glass: Contains a ground flat and parallel gasket surface suitable for sealing in any flange. We anneal our standard edge glass for low-pressure applications.

- High-Pressure Annular Glass: Our high-pressure glass is suitable for high thermal shock applications.

Annular glass has a range of applications across multiple sectors:

- Medical and Biomedical Research: Much medical and biomedical research revolves around the use of cutting-edge technology, which requires high-grade precision medical glass. Our surface lapping and polishing ensures precise parallelism and extreme flatness on all-glass substrates, suitable for any research.

- Petrochemical Applications: Many oil, gas, and other petrochemical tanks require high-pressure processes. Low-grade glass can be a weak spot in an otherwise sound high-pressure system. Our annular edge glass ensures your petrochemicals are safe.

- Pharmaceuticals: Pharmaceutical contents are highly valuable and delicate. Our annular edge glass provides a perfect seal, ensuring safety from outside contamination.

- Other industries that use annular edge glass sight windows include steam plants, electrical plants, and energy companies, among others.

Annular Edge Glass From Swift Glass

At Swift Glass, our team can craft unique and ideal glass solutions suitable for any project, ranging from the unusual or special to standard requests across a wide range of industries. We serve industries from military to medical research and are proud to serve our specialty glass. If you would like to learn more about our Annular Edge Glass, contact us today!