The Role of 3D Printing in the Manufacturing World

3D printing—also known as additive manufacturing—is a manufacturing process that creates physical objects from a digital model. It uses a specialized fabrication unit—i.e., a 3D printer—to add successive layers of plastic or metal material to form a 3D component. Compared to other manufacturing methods, it offers greater versatility, better cost-efficiency, and faster production speeds, especially for prototyping and small volume production runs. For these reasons, more and more manufacturers across a wide range of industries are turning to it for their product development projects.

While 3D printing is now the go-to technique for prototyping, it has also found increasing use as a primary production method in recent years. As the technology continues to develop over time, it is likely to rise even more in popularity. As a result, the demand for quality 3D printing supplies—including the printing bed—will increase too.

The Importance of the Printing Bed

The printing bed—also referred to as the build plate or print surface—is one of the most important parts of any 3D printer. It serves as the platform on which objects are 3D printed. While its primary function is providing a flat surface for the bottom layer of the print, its secondary function is providing an adhesive surface or a surface on which adhesive can be applied. Both ensure the print remains stable as it is created.

Materials for 3D Printing Beds

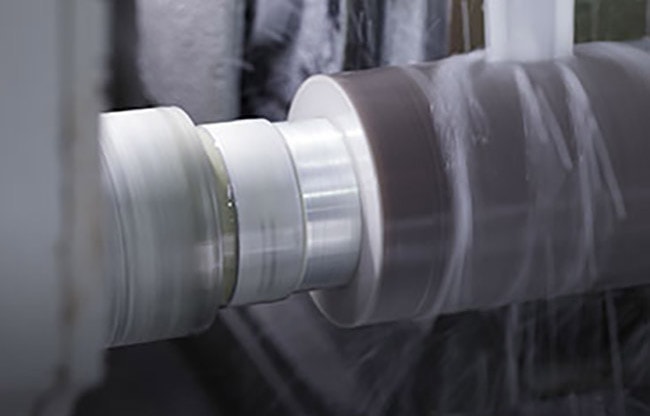

Printing beds are available in many variations, differing in material, surface finish, thermal characteristics, price point, and more. While they are traditionally made from metal or plastic, glass printing beds have become more ubiquitous.

Glass sheets are a simple and effective solution for print surfaces. Compared to other printing beds, they offer the following advantages:

- They are stiff and flat, meaning they will provide a solid and stable print surface for years.

- They have high material density and low thermal conductivity, which results in a longer heat up time but better heat distribution.

- They offer smoother surface finishes, making it easier to remove a finished print creating a nicer finish on the bottom surface.

Glass printing beds with heating capabilities further enhance prints by allowing for better material adhesion, a lower risk of material warping, and easier component removal.

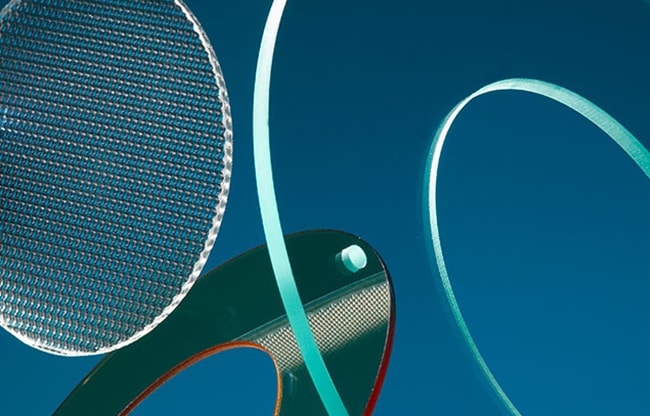

Two of the most common types of glass used for 3D printing beds are:

- Borosilicate Glass. This specialized glass contains a high concentration of boron trioxide and silica. It is characterized by its high durability and low coefficient of thermal expansion. When exposed to high temperatures, it remains clear, strong, and dimensionally stable.

- Clear Float Glass. Clear float glass materials (e.g., soda lime glass) are a low-cost alternative to borosilicate glass. They have lower durability and a higher coefficient of thermal expansion, which make them better suited for 3D printing applications involving lower temperatures and/or more flexible tolerance requirements.

Glass Printing Beds From Swift Glass

Need glass printing beds for your 3D printer? Swift Glass is here to help! We’ve manufactured industry-leading glass components for over 100 years. This experience enables us to provide high-quality glass cutting and edging services for customers who need glass 3D printing beds. Whether you need borosilicate or soda lime printing beds, we’ve got you covered. We can produce them in a variety of shapes, sizes, and quantities to suit virtually any 3D printing need.

To learn more about our custom glass 3D printing beds or discuss how we can help with your next project, contact us today.