Swift Glass holds its commitment to fabricating products to the highest quality in the utmost regard.

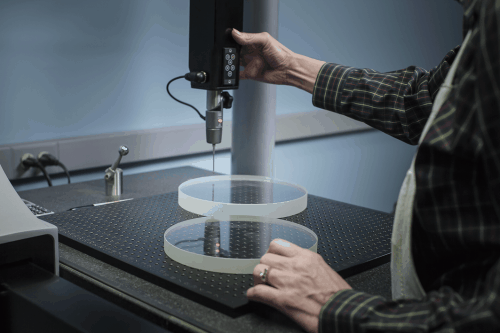

Every order, regardless of whether it is one prototype, small quantities or a large volume production, passes through several extensive levels of quality control. These processes include first-piece inspection, random sampling and final checks just before shipment.

Tools which we employ to aid in these quality checks are:

Tools which we employ to aid in these quality checks are:

- Coordinate Measuring Machine (CMM)

- Optical Comparator

- Photoelastimeter

- Polarimeter

- Differential Surface Refractometer (DSR)

- Grazing Angle Surface Polarimeter (GASP)

- Surface Profilometer

- High Powered Microscope

- Interferometer

- Optical Flat

To complement the functions of the above-mentioned inspection tools, the Swift Glass team recently added an ISO Class 7, (Class 10,000,) clean room and capabilities of ultrasonic bath cleaning and wafer measurement.

Wafer Measurement Capabilities

The addition of a Tropel® FlatMaster® MSP-300 frequency stepping interferometer to our state-of-the-art inspection facility allows us to provide precise wafer measurement capabilities, inclusive of wafer thickness and flatness across the wafer’s entire surface. By using this high-frequency tool, our technicians can collect more than three million submicron-level data points within a few seconds.

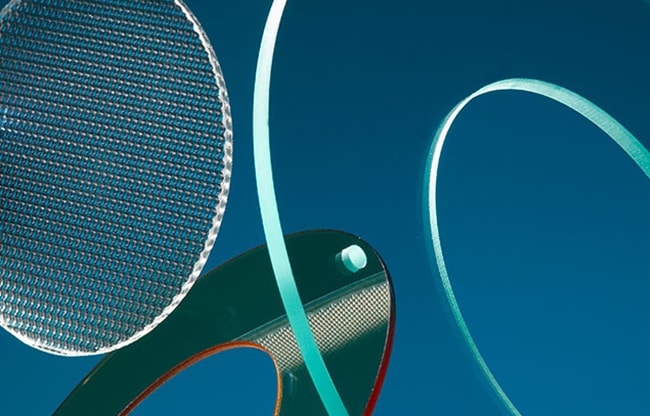

This new tool is a sought after addition to our already extensive list of advanced capabilities which include:

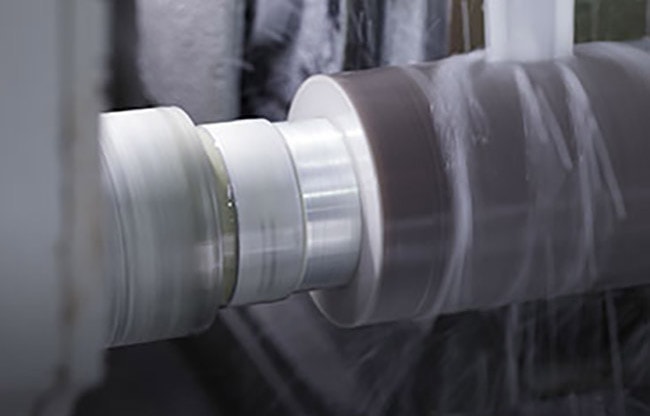

- CNC machining

- Surface lapping

- Glass drilling

- Thermal glass tempering

- Waterjet and glass cutting

- Chemical glass strengthening

- Surface polishing

- Edge polishing and grinding

Contact Swift Glass Today

As an ISO 9001:2015 certified and ITAR registered company, Swift Glass understands the importance of providing high-quality glass parts. That is why we look to continuously improve our facilities and expand our fabrication and inspection offerings —such as adding the ISO Class 7 Cleanroom, Ultrasonic Bath, and Multi-Surface Profiler—to provide customers with superior solutions.

To learn more about our inspection process and the capabilities we offer, contact us today.