The field has grown astronomically since the invention of the laser and now encompasses everything from disc-based data storage to cutting-edge imaging technologies.

Various sectors make use of photonics, including telecommunications, construction, aviation, medical, and metrology, and other diverse applications continue to emerge. Remaining constant across all photonics applications, however, is the need for high-quality glass components.

Speaking broadly, the types of glass used in photonics are not dissimilar from the glass used in any other application. For example, the silicate materials used in photonics glass are also used in several other industries, and the same types of grinding, polishing, and surface finishing processes are applied as well.

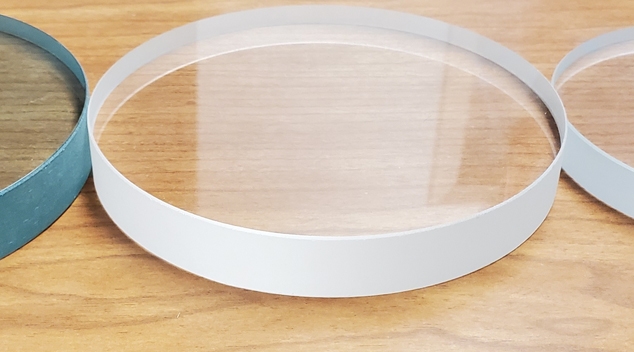

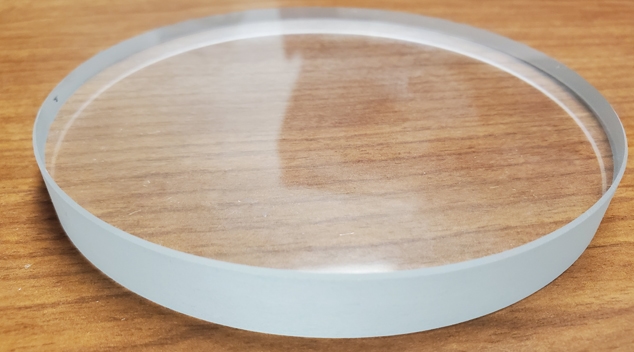

Unlike the glass used in other industries, however, photonics glass must meet tight tolerances to suit the delicate applications in which the glass is used. Many companies can’t produce glass to these unique specifications, but the team at Swift Glass can, offering some of the tightest tolerances in the industry.

Tolerances

At Swift Glass, we work hard to keep the tightest tolerances possible through the use of cutting-edge machinery and equipment, much of which we design and build in-house to our own custom specifications. We also employ stringent testing processes to ensure quality and reliability.

We can manufacture wafers as thin as 0.3 mm and are working toward the goal of 0.17 mm. We maintain tolerances as tight as 1 micron for flatness — an extremely important requirement in photonics applications — and perform total thickness variation (TTV) checks in nine places per part.

If you need assistance calculating the measurements of your glass part, check out our Micron to Fringe to Wave Conversion Tool.

Materials

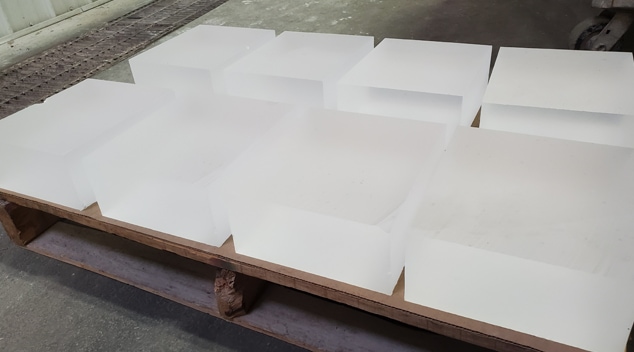

The vast majority of photonics glass is either borosilicate or fused silica. Though not unique to photonics, these materials are ideal for the industry; they are dense, stable, and rigid, and have good thermal expansion rates. Quartz glass is also becoming more and more popular, particularly in laser cutting applications. Committed to constant improvement, Swift Glass is currently testing N-BK7 — a borosilicate variety of glass — for feasibility in photonics applications.

Ready to get started?

Contact us today to learn more about Swift Glass’s photonics capabilities, including our ability to meet specific requirements for a range of applications, such as mirrors, MEM, computer chips, medical imaging, and lasers.