Swift Glass Company has nearly a century of experience developing and fabricating high-quality glass parts for diverse industries. Among our specialties is optical glass. Our team has vast experience working with original equipment manufacturers (OEMs) in the optical sector, so we understand the complexities and rigorous industry standards involved in making effective optical products.

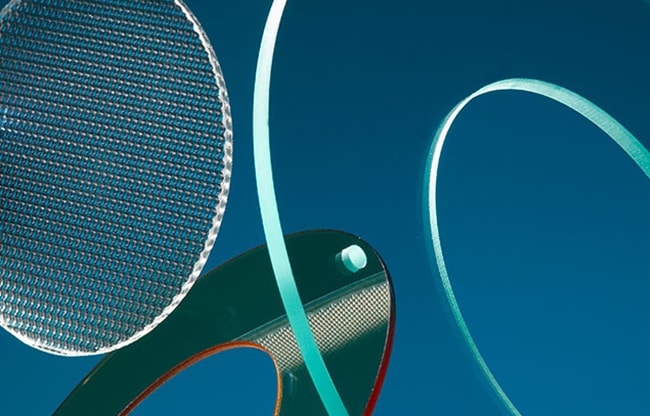

To that end, we offer custom optical lens blanks made of quartz, crown glass, or fused silica with the ideal chemical, mechanical, and optical properties to meet your requirements. Learn more about glass blanks and the advantages to using precision-machined optical products from Swift Glass for your project.

Benefits of Swift Glass Precision Optical Blanks

Manufacturing specialty glass lenses is a very complex process necessitating precision work. The glass must properly absorb, refract, and transmit light at different wavelengths per the intended application. By facilitating the production process with high-quality blanks already shaped and sized to your specifications rather than starting off with raw material, however, your team can better streamline production and reach your project goals — all without sacrificing quality.

When using optical blanks from Swift Glass for producing lenses, you’ll benefit from the following:

- Near net shape. Our manufacturing processes produce raw parts very close to the desired shape or dimensions via time-tested and highly specialized fabrication techniques.

- Decreased costs. Our precise and efficient process for creating near-net shape blanks ensures streamlined fabrication with minimal material waste generation. As a result, you save on reduced material and labor expenses.

- Reduced handling. Traditional lens manufacturing processes require excessive handling, which takes longer and risks product damage. Alternately, pre-machined blanks significantly decrease the amount of handling required for your lenses, enhancing efficiency and quality results.

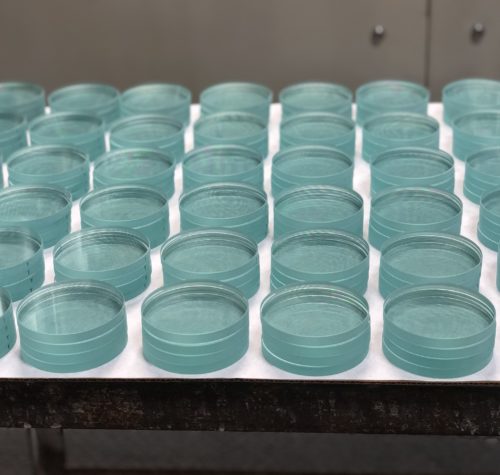

- Expedited delivery. Working with pre-machined blanks is also faster, even in large numbers, as they significantly cut down on processing time. Your customers can receive manufactured lenses with shorter lead times, and your operation can maintain a tighter production schedule.

At Swift Glass, we fabricate and manufacture everything from optical tools and custom optical wedges to precision optical components and spherical optical blanks. Our team prioritizes surface quality and finish along with performance and cost-effectiveness to ensure you’re starting your optical lens project with superior blanks.

We have the capacity to fulfill high-volume orders from prototype to production, even within tight turn times. Also, we’re used to complying with stringent regulations in demanding industries. Our full-service company is ISO 9001:2015 certified and ITAR registered, and we can also meet ASTM standards and MIL-Spec requirements, for example.

Our blanks are available in a wide range of sizes and shapes for your convenience, including options like prisms, discs, cubes, and rectangles. We fabricate custom glass blanks from multiple material selections based on your unique specifications.

Glass Blank Specifications and Tolerances

To comply with the necessary standards for optical glass products, the Swift Glass team provides glass blanks within your preferred tolerance range. See the chart below for our specifications and tolerance capabilities.

| Diameter | Within .001” |

| Flatness | ¼ wave |

| Parallelism | .0001” – .0005” |

| Surface Finish | 20/10 – 60/40 |

| Specification | Specification |

|---|---|

| Diameter: | .100” – 28” |

| Thickness | .007” – 3.5” |

| Rectangle Sizes | .042” – 36” |

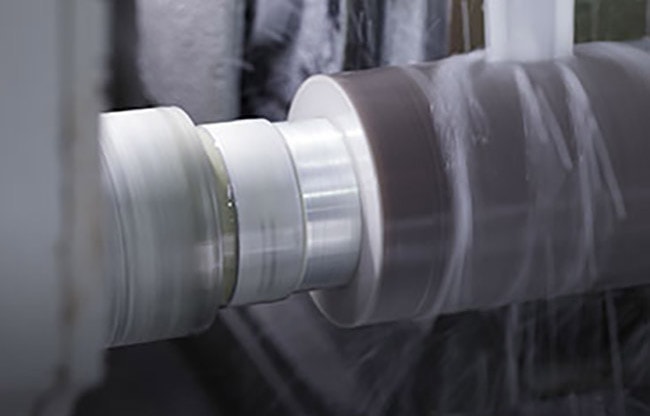

Advanced CNC Machining Techniques for Precision Glass Blanks

Our in-house fabrication capabilities are comprehensive. Among our core competencies are our precision CNC machining capabilities, which enable us to provide accurate lens blanks per your specifications. Our optical glass CNC machining processes include:

- Waterjet cutting

- Boring

- Engraving

- Drilling

- Slotting

- Pocketing

- Surfacing

- Grooving

Glass Blank Material Options

At Swift Glass, we partner with leading glass manufacturers to ensure we’re using materials of the best possible quality. For precision glass blanks, we offer the following material options based on your needed performance and glass physical property requirements:

- Quartz

- Crown glass, SCHOTT® N-BK7

- Fused silica

- Corning® 7980 Industrial

- Corning® 7980 UV Grade

Contact Swift Glass for Precision Glass Blanks

When you need custom optical precision glass blanks, the team at Swift Glass is here to help. Each of our employees is committed to excellence and serving our OEM clients around the globe with a cutting-edge solution to their specialty glass part needs. Contact us for more information on how Swift Glass supports the optical industry, or request a quote today for pricing details.