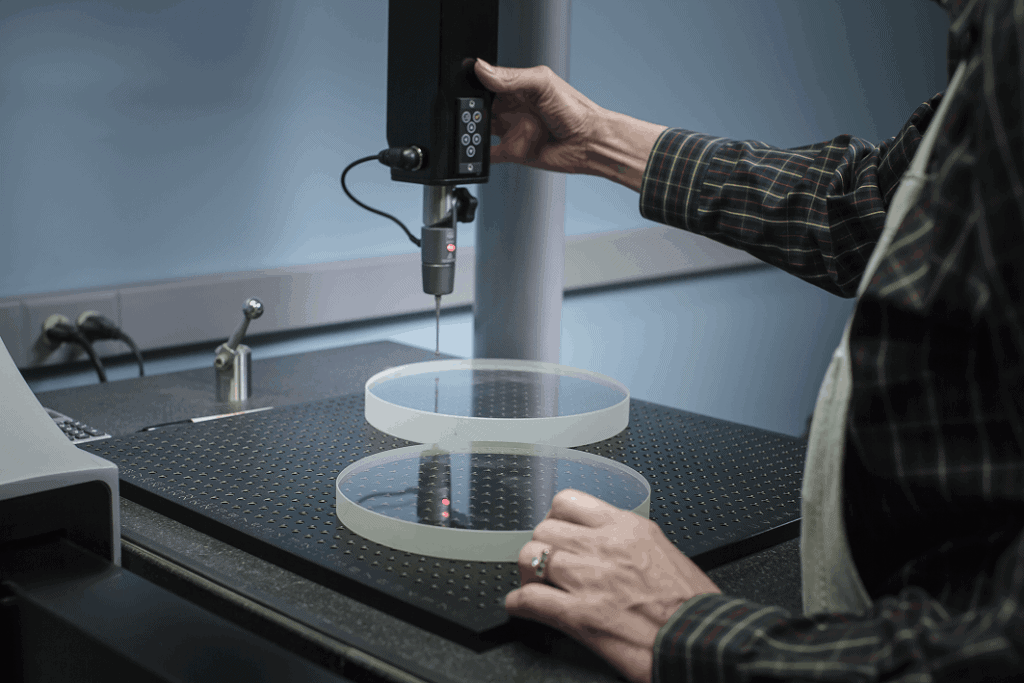

CMM inspection is an advanced inspection technique that uses coordinated measurement machines (CMM) and software to check dimensions and GD&T features in fabricated glass components. This method can be used at multiple stages of the production process, allowing for greater precision and efficiency.

At Swift Glass, we are committed to providing quality CMM inspections for our customers. Our coordinate measuring machines replace conventional tools and techniques, streamlining inspections and elevating the quality of fabricated glass products. Learn more about CMM services, the advantages they provide, and our CMM inspection capabilities at Swift Glass.

Accurate CMM Services for Quality Control in Glass Fabrication

Our technicians use coordinated measurement machines (CMM) to check dimensions and GD&T features in fabricated glass components as part of a comprehensive quality control effort. These machines can find the exact measurement of three-dimensional objects, known as the true position measurement. Our technicians can then compare the results with the intended design and verify that the given feature will be successful in assembly.

Advantages of True Position Measurement with CMM

Compared to manual measurement, using a CMM to obtain true position measurement offers numerous advantages. These include:

- Enhanced Efficiency. When using a CMM, a measuring probe moves along predefined paths, taking measurements at specific points along the X, Y, and Z axes. This eliminates the need to manually manipulate and set a probe for each measurement.

- Higher Accuracy. Our CMM uses integrated software to calculate the true position. It can provide estimations in the micrometer range, which is highly valuable when working with glass components that must meet tight tolerances.

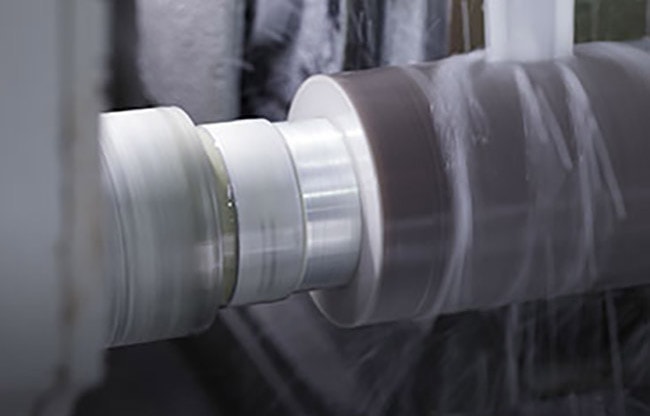

- Greater Flexibility. Our CMM offers similar functions to our Comparator machine, but with added maneuvering flexibility. We can use our CMM with glass parts of varying shapes, sizes, and complexities.

Swift Glass’s CMM Inspection Capabilities

Quality and accuracy are important to us, which is why we use the TESA Micro-hite 3D CMM to inspect glass parts during and after fabrication. This machine uses a probe to complete data reading and advanced CMM software to calculate the true position measurement, quickly sharing the results on a connected display. It can take various types of measurements, including:

- Bevels

- Angles

- Length and Width

- Distance

- Thickness and Radius

- Holes and Imaginary Points

The TESA has a 17 x 17-inch range for inspection, measuring squares, rectangles, discs, and other shapes with ease. It can also be programmed to inspect and measure multiple parts simultaneously. This is especially useful with complex projects, as it allows our technicians to obtain hundreds of measurements in quick succession. The machine then saves all relevant data for reporting purposes.

Additional Inspection Tools

Swift Glass uses multiple inspection tools and methods along with our coordinate measurement machines to enhance quality control. These include:

- Optical Comparators

- Photoelastimeters

- Polarimeters

- Differential Surface Refractometers (DSR)

- Grazing Angle Surface Polarimeters (GASP)

- Surface Profilometers

- High Powered Microscopes

- Interferometers

- Optical Flats

Discover The Benefits of Swift Glass CMM Today

Incorporating automated technology like coordinated measurement machines ensures accuracy in fabricated glass components that must meet tight tolerances. As an ISO 9001:2015 certified and ITAR registered company, we understand the importance of accuracy and precision. We use CMM inspections to guarantee precision and high-caliber execution, resulting in higher-quality glass parts. We are constantly expanding our fabrication and inspection offerings, with additions such as our ISO Class 7 (Class 10,000) Cleanroom and Ultrasonic Bath to supply customers with the best possible solutions.

Contact us today to request a quote or to learn more about our inspection services.