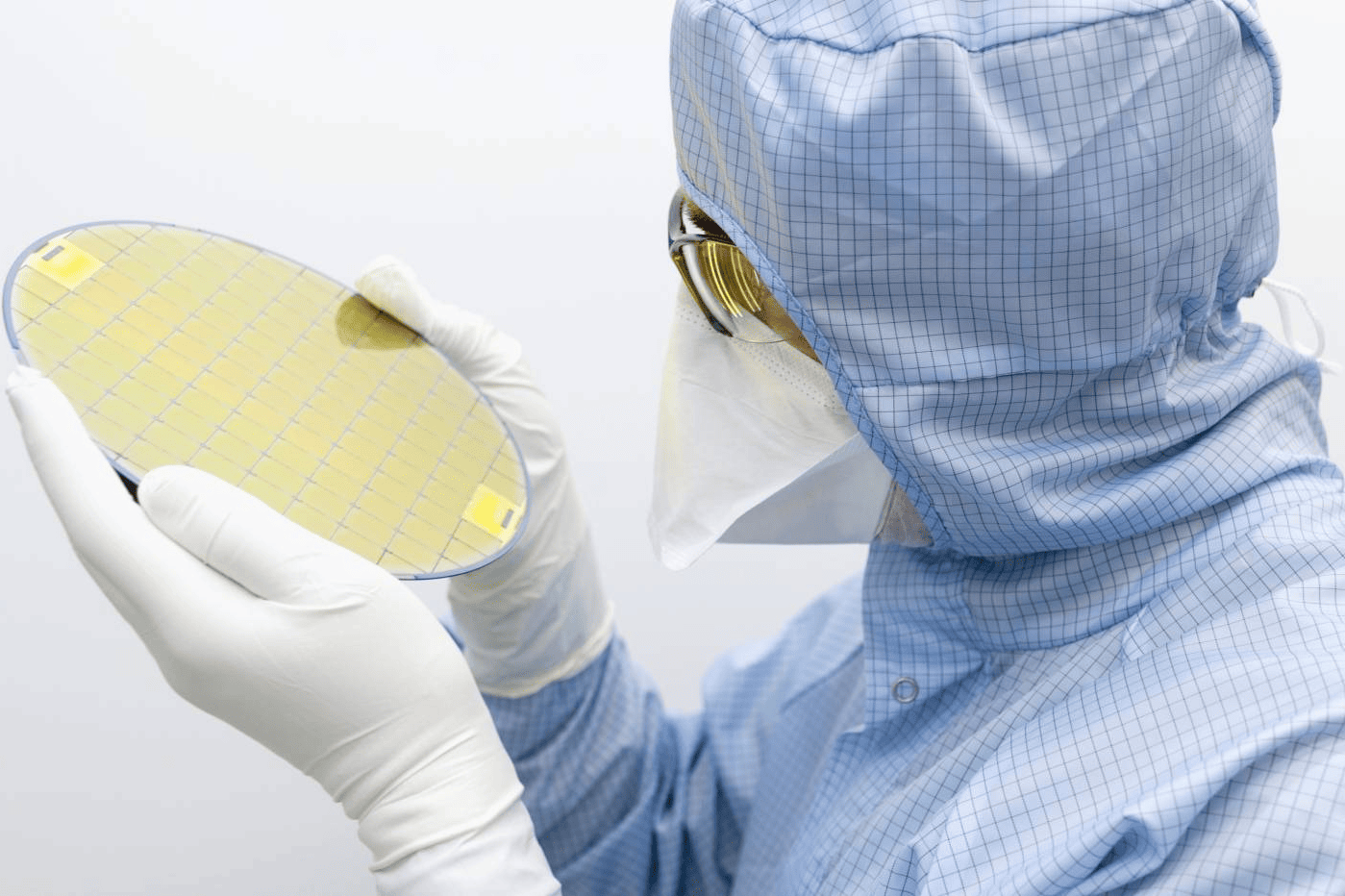

Ultra-thin glass wafers are essential components for semiconductors and sensors. Still, finding the right manufacturer to provide them can prove challenging. With a long-standing reputation as a top provider of custom-fabricated glass components, Swift Glass is a leading supplier of ultra-thin glass wafers. Our company holds ITAR and ISO 9001:2015 certifications to maintain consistent quality standards across our products.

Our ultra-thin glass wafers offer a few specific benefits, including reduced size and weight compared to other materials, low micro-roughness, and a smooth, flat surface. Together, these properties lend to optimized efficiency and performance in semiconductor and electronic applications.

Custom Ultra-Thin Glass Wafer Fabrication from Swift Glass

At Swift Glass, we manufacture fully customized ultra-thin glass wafer components for our customers. The following are some of the main features and advantages of working with us for wafer fabrication:

- Reliable expertise and experience. Swift Glass has nearly a century of experience developing custom glass components, leading to our recent developments in ultra-thin glass wafer products.

- Lower production costs. As a go-to fabricator, we work to provide customers with an all-in-one solution that includes material sourcing, fabrication, inspection, and finishing to save them precious time and money.

- Superior Quality. Our experts work to maintain high quality standards through our rigorous control processes and our ITAR and ISO 9001:2015 certifications.

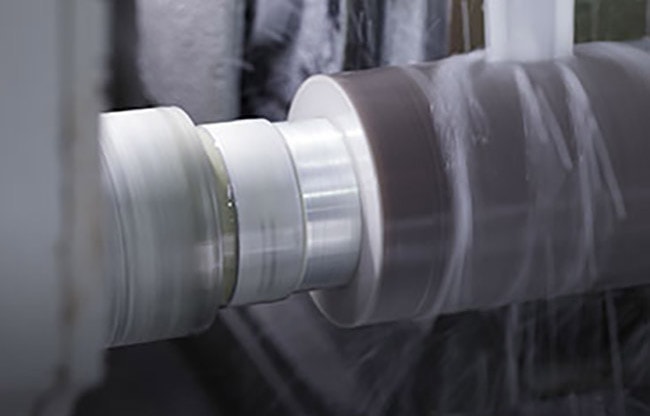

- Flexible customization capabilities. We work with each client to determine their precise needs and fabricate the most compatible glass wafer product for them. We can meet any requirements regarding flatness, edge profile, and surface quality, regardless of the intricacy or size of the design.

- Varying wafer thicknesses. Our capabilities enable us to fabricate glass wafers down to the micron level, making them some of the thinnest designs available.

- Adherence to SEMI standards. Our thin glass wafers comply with all SEMI standards, including dimensional, flat, and notch specifications. We can also incorporate alignment marks, holes, pockets, and other details for a fully tailored product.

- Fast turnaround times. Our vast inventory of in-stock materials and ability to manage all operations in-house help ensure quick turnarounds with every project.

- Secure shipping and handling. Plastic cases with interleafing material or wafer-specific carriers are used to securely package each wafer and minimize the risk of damage to products during shipping.

| Wafer Diameter | Wafer Thickness |

|---|---|

| 200mm | 0.3 microns (0.0003 millimeters) |

| 300mm | 0.5 microns (0.0005 millimeters) |

Ultra-Thin Glass Wafer Materials

We use various top-quality materials to fabricate our ultra-thin glass wafers, including:

Borosilicate

Borosilicate is a specialized glass comprising highly concentrated boron trioxide and silica, offering reliable thermal stability and durability. We offer a couple of borosilicate materials that offer unique properties and advantages:

- Corning Eagle XG®. This eco-friendly, low-density glass offers excellent thermal properties, with a low density, high resistance to chemicals, and high surface quality.

- Schott BOROFLOAT®. Another environmentally friendly option, this lightweight float glass is highly resistant to heat and chemicals, with superior transmission properties.

Quartz

Another quality option we offer is quartz. This material offers high temperature resistance, chemical purity, and dimensional precision. Its thermal and optical properties make it a superior option for semiconductor fabrication and lab equipment.

Fused Silica

Fused silica is the purest form of glass, featuring a noncrystalline structure. It offers near-zero thermal expansion, high UV transparency, and reliable thermal shock resistance. Due to fused silica’s high purity, it is widely used in semiconductor parts.

Ultra-Thin Glass Wafer Applications in Semiconductor and Sensor Technologies

Ultra-thin glass wafers from Swift Glass enable smaller, more sensitive, and more efficient sensors and microelectromechanical system (MEMS) devices. By enabling the miniaturization of sensors, they can support applications with space constraints, such as wearable electronics, the Internet of Things (IoT), and more. Our ultra-thin glass wafers also enable the use of advanced technologies such as 3D stacking and fan-out wafer-level packaging (FOWLP). Photonics, microfluidics, and flexible electronics are some other examples of applications that use thin glass wafers like ours.

We can also provide ultra-thin glass wafers for biomedical and environmental sensors. Applications such as implants, diagnostics equipment, water quality analysis, and air quality monitoring can all benefit from increased sensitivity and reliable performance.

Partner With Swift Glass for Your Next Semiconductor or Sensor Project

Seeking high-quality ultra-thin glass wafer products for use in a semiconductor or sensor? You’ll find plenty of great custom options here at Swift Glass. We have extensive expertise, experience, and in-house resources to complete nearly any type of project. We guarantee superior quality while meeting SEMI standards for wafers. We also maintain ITAR- and ISO 9001:2015 certifications, backing our reputation as a trusted partner in custom-fabricated glass components.

For additional information about our customizable solutions or other offerings, contact us today and speak with a member of our team. You can also request a quote for a custom product based on your unique specifications.