As an industry-leading glass fabrication services provider for businesses worldwide, Swift Glass Company offers nearly a century of expertise in processes ranging from glass CNC machining to edge grinding and polishing. One of our many on-site specialties is quartz wafer fabrication. Read on to learn more about what quartz wafers are, their common applications, and how the team at Swift Glass can support your operations with high-quality, custom quartz wafers created per your exact specifications.

Quartz Wafers 101: Properties and Benefits

Quartz, an abundant and naturally occurring mineral, is made up of silicon dioxide crystalline forms. It exhibits high melting and working temperatures and possesses high chemical purity, along with precise dimensional tolerances. When manufacturers engineer quartz in artificial crystals, they can slice the extremely pure, cultured material into individual wafers.

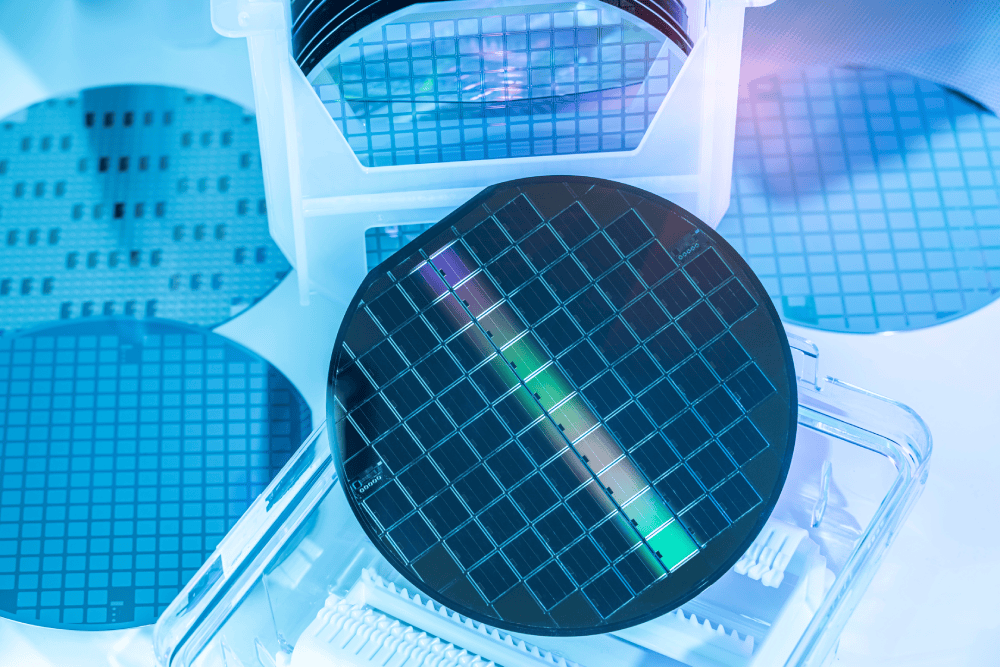

Quartz wafers are thin disks or plates of varying thicknesses and sizes, typically falling between 0.02 and 0.25 inches and approximately 2 to 12 inches in diameter, respectively. These circular wafers of synthetic quartz crystal function as temporary or permanent substrates upon which manufacturers can develop optical and electronic devices for myriad applications. It’s the crystalline structure within these wafers that gives them their beneficial properties. Quartz wafers offer good transparency, purity, chemical and thermal stability, resistance capabilities, and more.

Quartz material is often used interchangeably with fused silica in specialized applications. Both materials are highly pure and amorphous and have exceptional optical characteristics, low coefficients of expansion, and high temperature resistance. Compared to fused silica, however, quartz is natural, has a low OH content, and contains some residual impurities from its raw form that impact its ultraviolet (UV) transparency. Fused silica, the purest form of glass, is a fully synthetic material. It exceeds quartz in UV performance, making it a better choice for applications involving UV transmitting optics. Of the two, quartz excels in infrared transparency applications.

Common Uses for Quartz Wafers

Quartz wafers are highly versatile, lending them to applications across diverse industries. Some prominent examples include:

- Semiconductor manufacturing. When producing semiconductors, quartz wafers are actually the basis for these devices. They’re chemically inert products, offering a chemically and thermally stable platform foundation upon which to fabricate chips. Also, quartz is an exceptional electrical insulator, and the material handles radio frequency signals particularly well.

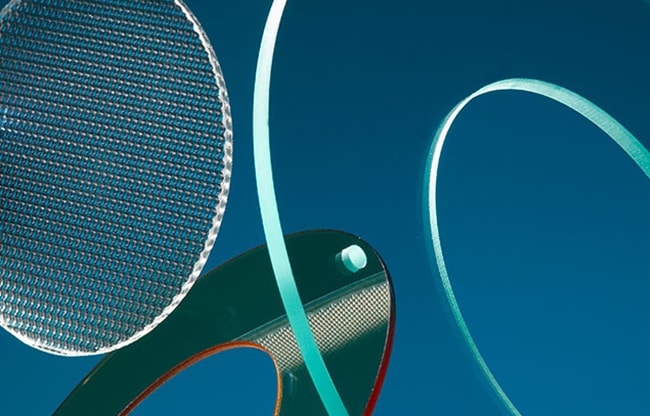

- Electronics. Quartz wafers are a high-purity product, making them an ideal choice for quartz crystal oscillators and optoelectronics. Given their impressive transparency, they’re important components for manufacturing products like optical lenses and fibers. The wafers also exhibit minimal thermal expansion, allowing them to maintain their integrity in high-heat electronic applications.

- Research and development. In R&D operations, you’ll find quartz wafers in equipment throughout the lab. Tubes, boats, crucibles, optical cells, and more rely on wafers of this material for their resistance to high temperatures, chemicals, and corrosion. They’re also typically a part of pressure sensors, accelerometers, and various other microelectromechanical systems (MEMS). They’re beneficial for their ability to transform mechanical energy into electrical energy.

Custom Quartz Wafer Fabrication at Swift Glass

Swift Glass uses only the highest-quality materials to fabricate our custom glass wafers. In quartz, we have several material options, including:

- GE® 124. Consisting of crystalline silica, this highly pure fused quartz is quite similar to fused silica. However, GE® 124 has a lower OH content and less UV spectrum transmission. It’s beneficial for its high chemical and thermal resistance.

- Hereaus TSC-3®. Another high-purity material, this standard quartz glass has low bubble content, making it an ideal option for etch systems and equipment involved in semiconductor production.

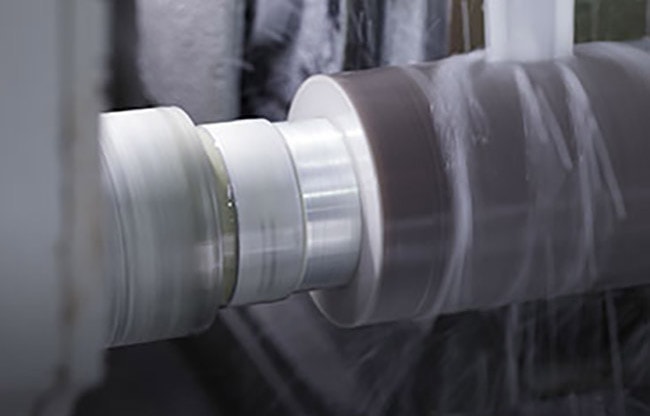

Our skilled team, backed by our company’s nearly 100 years of industry expertise, is among the most experienced in our field. We use advanced cutting and finishing equipment to produce custom wafers of the desired size, flatness, thickness, edge profile, and surface quality, per your specifications.

As an ISO 9001:2015- and ITAR-certified company, we’re committed to quality in all stages, from design to production. We’re experienced in meeting all applicable industry quality standards to ensure top craftsmanship in our fabrications. In addition to our fabrication capabilities, Swift Glass can assist you in perfecting your custom quartz wafer design.

Ready to Discuss Your Project? Contact Our Glass Experts Today.

If you’re looking for quality, high-purity quartz wafers for your next project, the Swift Glass team is here to help. With proven capabilities for custom glass fabrication, cutting, tempering, polishing, and more, we can meet your unique product specifications with in-house, turnkey services. Contact us for more information on our custom quartz wafers and fabrication capabilities, or request a quote today.