Swift Glass is an industry-leading manufacturer of quality fabricated glass components, including fused silica wafers. Using advanced glass manufacturing technology and high-quality materials, we can fabricate both standard and customized fused silica wafters to meet the unique needs of your industry or application.

High-Quality Fused Silica Wafers from Swift Glass

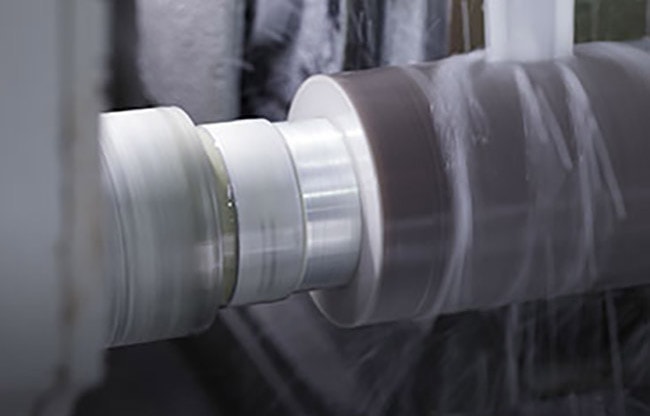

The experts at Swift Glass utilize innovative cutting tools, advanced finishing machines, and superior glass materials to fabricate high-quality fused silica wafers. To meet a range of project needs, we can customize fused silica wafers based on your requirements for thickness, flatness, edge profile, and surface quality. Our skilled team not only assists with fabricating your custom design but will also help you refine and perfect it.

Using highly precise waterjet cutting machines, we can achieve wafer thicknesses as low as 0.1 mm with exceptional accuracy. We are also ISO 9001:2015 and ITAR certified, guaranteeing adherence to the highest quality standards.

What is Fused Silica?

Fused silica is a synthetic, non-crystalline material that is known as the purest form of glass. It is made either by melting silica grains into a single form or by using chemicals to synthesize the glass. Regardless of the production process, the result is a cohesive, cross-linked 3D structure that features excellent UV transparency, thermal shock resistance, and near-zero thermal expansion. Swift Glass works with the following varieties of fused silica:

- Industrial fused silica. This is commercial-grade fused silica, often used in sight glass applications.

- UV-fused silica. This type of fused silica is best for applications requiring a low inclusion content and/or high refractive index homogeneity.

In addition to fused silica wafers, Swift Glass can also fabricate quartz wafers. While these materials have many similarities and are often interchangeable, fused silica offers the highest temperature characteristics and improved ultraviolet performance compared to quartz.

Common Applications of Fused Silica Wafers

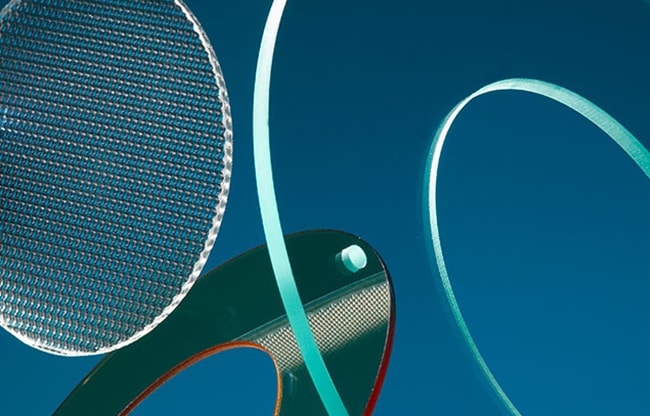

Due to the many advantageous properties of fused silica wafers, they can be used in a wide range of laboratory, commercial, and industrial applications. Some of the most common include:

- Semiconductors. The high purity of fused silica wafers makes them ideal for the semiconductor industry. From photolithography processes to creating microchips and other electronic components, fused silica wafers are invaluable to semiconductor manufacturing.

- Optics and photonics. Fused silica wafers are often used for precision optical components such as lenses, mirrors, and optical fibers. They can also be used in laser systems, telescopes, and other optical instruments.

- Scientific research. Fused silica wafers are utilized for numerous laboratory and research applications, including spectroscopy, microscopy, materials science, and more.

Contact Swift Glass for Your Glass Wafer Needs

Swift Glass is your trusted partner for custom fused silica wafer fabrication. We offer unmatched expertise and precision in every project we undertake. Our unwavering commitment to quality and innovation ensures we meet and consistently exceed our customers’ expectations. With decades of experience and access to cutting-edge technology, we deliver tailored solutions designed to align with your unique requirements and specifications.

Whether you need standard wafers or custom designs, our team is here to help you achieve exceptional results. Ready to discuss your project? Contact us or request a quote today to get started!