Category Archive: Tempered Glass

As a particularly strong material, tempered glass is fabricated to provide optimal durability and safety for diverse projects. It’s applicable in everything from residential settings and consumer goods to industrial facilities and construction sites. Learn more about this versatile glass, its primary benefits, how it’s made, and its ideal applications.

What is Tempered Glass?

Tempered glass is a strengthened glass that’s ideal for applications in which standard annealed glass wouldn’t be sufficiently strong. Also referred to as safety glass or toughened glass, manufacturers produce this product by heat-processing the glass, resulting in a material that’s as much as four times stronger than traditional glass.

The material achieves this through a delicate balance of interior tension and surface compression, with a minimum of 10,000 psi of compressive stress. Once you temper glass, however, it’s in its final state. You can’t make any additional cuts, drill holes, add etching, or polish the glass without upsetting the mechanical stresses and potentially shattering the material.

Many industries utilize this versatile glass to create durable products that must withstand specific thermal conditions. For instance, building codes will sometimes specifically state that tempered glass must be used as it lends a higher degree of safety and protection to an application. It’s also ideal for high-contact surfaces and products for its added toughness.

Tempered Glass Properties & Benefits

Tempered glass offers numerous advantages compared to regular glass. The benefits of tempered glass include:

- Increased safety. The primary advantage of tempered glass is that, in the event that it does shatter, the glass will break into small, dull pieces. This decreases the likelihood that someone will sustain injuries from broken glass shards.

- Enhanced strength and durability. Tempered glass is significantly stronger than standard glass varieties, allowing it to hold up well against pressure and impact. It’s also resistant to everything from abrasion to chemical exposure.

- Resistance to high-heat conditions. The heat resistance of tempered glass lends it to applications in high-heat industrial equipment like windows for a furnace.

- Good clarity for optimal visibility. Regardless of application, tempered glass maintains its transparency, making it an ideal option for observation windows to monitor operations.

- Application versatility. Between its strength and its resistance properties, tempered glass is ultimately a highly versatile material option for diverse applications.

Common Tempered Glass Uses

(Click to Expand)

So, what is tempered glass used for? Tempered glass is common for architectural features like windows, skylights, doors, and partitions, but it has an extensive array of uses ranging from consumer products to industrial applications. This glass type is well suited to products such as:

- High-pressure and explosion-proof windows

- Fire department access panels

- Safety door windows, space partitions, and related industrial facility features

- Protective safety guards and windows for machinery

- Glass lab equipment that can withstand both high heat and chemicals

- Transparent covers or enclosures for gauges, sight glass, and other instrumentation

- Glass walls for elevators or stairways

- Side and rear vehicle windows

- Frameless shower doors and glass walls

- Refrigerator shelving, oven door observation windows, stovetops, and appliance components

- Lighting fixtures

- Decorative panels for added aesthetic appeal in interior design

- Display cases and cabinets

- Glass tabletops

Understanding The Glass Tempering Process

But how is tempered glass made? Manufacturers create this product by heating, or tempering, the glass. The tempering procedure involves a few steps:

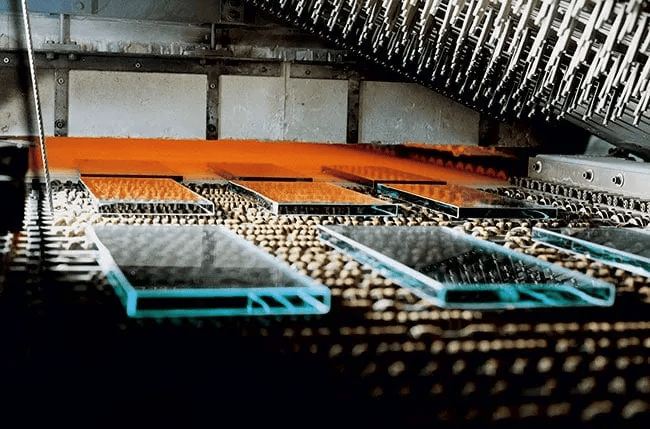

- Heating. The glass first moves through a high-heat tempering oven, which raises the temperature of the glass to approximately 1200° F as part of a highly controlled process. This temperature falls between the higher deformation temperature and the lower strain temperature of the glass.

- Quenching. After the oven sufficiently heats it, manufacturers then quench the glass, cooling it down. A very fast process, quenching involves multiple nozzles that blast the material with cool air for several seconds. This dramatic thermal shock is how tempered glass comes by its strength. The surface and edges of the material compress and the inner layer is in tension, resulting in glass that’s three to five times as strong as traditional varieties.

>> Thermal Glass Tempering vs. Chemical Strengthening: What’s the Difference?

Contact Swift Glass: Your Source for High-Quality Tempered Glass Solutions

Whether you have a small or large project, you can feel secure in the knowledge that Swift Glass offers only first-rate, carefully inspected tempered glass parts. Our expert thermal glass tempering services are of the highest quality.

In addition to our tempering capabilities, our experienced team of specialists also provides chemical strengthening, CNC machining, ultra-high-pressure cold cutting, drilling, polishing, and printing services for turnkey results.

To learn more about the advantages of tempered glass, download our eBook, “Creating Glass That Withstands Extreme Environments,” or contact us with any further questions.

Mining equipment must function seamlessly amid extreme conditions. The choice of materials can significantly impact project safety, productivity, and efficiency. For example, tempered glass must be used instead of annealed glass for certain applications because tempered glass can withstand the high temperatures and corrosive conditions of mining environments. Swift Glass delivers high-quality tempered glass solutions tailored to the mining industry’s unique needs.

Discover the benefits of tempered glass and how our products are utilized in the mining industry.

Elevate Your Mining Operations: The Benefits of Tempered Glass

Temperature Resistance

Mining equipment is exposed to a wide range of temperatures, from the intense heat of machinery to cold storage areas. Tempered glass, such as the tempered glass barrier plugs we produce, excels in these extreme conditions, maintaining its integrity and functionality amid temperature fluctuations. This temperature resistance is vital for applications such as lighting fixtures and enclosures, ensuring they perform reliably in any environment.

Safety

The safety benefits of tempered glass over annealed glass are important. When tempered glass does break, it shatters into small, blunt pieces that are far less likely to cause injury. This safety feature is particularly important in mining, where the risk of injury is heightened. Our tempered glass plugs are tempered in an oven to a certain strength level so that, when operating pressures surpass a specific limit, they break apart as needed. Other applications like machine windows and control panels become safer with tempered glass, protecting workers and equipment alike.

Durability

Thermal tempering enhances the glass’s strength, thermal shock resistance, and impact resistance. This durability is essential for mining equipment, which is exposed to abrasive materials, heavy loads, and sudden temperature changes. By improving the durability of glass components, mining operations can reduce downtime and maintenance costs.

The Swift Glass Advantage

Why choose Swift Glass for your mining glass needs? Our expertise in thermal glass tempering sets us apart. We are an ISO 9001:2015 certified and ITAR-registered company, adhering to strict mining industry standards. With nearly a century of experience in glass fabrication, Swift Glass is a global leader in providing innovative glass solutions to industries from aerospace to biomedical to optical to mining. In addition to thermal tempering, we provide a range of additional capabilities:

Swift Glass offers a range of thermal glass tempering capabilities, designed to meet the diverse needs of the mining industry. We can handle large sizes, custom shapes, and specialized coatings, ensuring that each piece of tempered glass is perfectly suited to its intended application. Swift Glass provides solutions for heavy machinery, protective windows, barrier plugs, and other mining applications.

Additional Resources

Click one of the eBooks below to learn more about the different types of glass we offer.

Contact Swift Glass: Your Reliable Partner in Mining Glass Solutions

In mining, selecting the right materials ensures operational efficiency, personnel safety, and equipment longevity. Tempered glass, renowned for its exceptional durability, enhanced safety features, and remarkable temperature resistance, is the superior choice for a wide range of mining applications. Swift Glass offers tempered glass solutions designed and engineered to meet the mining industry’s stringent requirements.

Contact us today or get a free quote to learn how our thermal glass tempering solutions can benefit your mining operations.

High performance glass is in demand for a variety of applications that require durable and reliable glass products, including windows for industrial and safety applications that must withstand bullets, explosions, and high pressure. In addition to windows, high performance glass is useful for industrial lighting products, military, medical and many other applications.

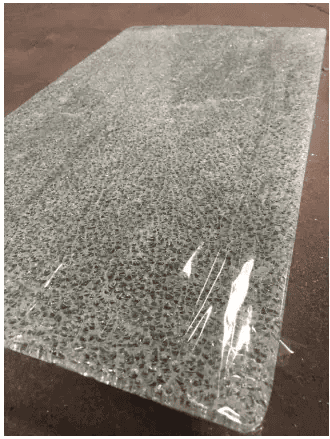

High Performance Glass Stress Points

The value of high performance glass comes from its high breaking point and the manner in which it breaks. Rather than shattering into long, sharp pieces like standard annealed glass, high performance, or tempered, glass breaks into small pebble-shaped pieces that are less likely to cause severe injury.

The value of high performance glass comes from its high breaking point and the manner in which it breaks. Rather than shattering into long, sharp pieces like standard annealed glass, high performance, or tempered, glass breaks into small pebble-shaped pieces that are less likely to cause severe injury.

High performance glass is used particularly in situations where certain external forces would break untreated glass, as it can withstand stress more easily. It is especially useful in applications where the following factors may be encountered:

High Pressure

High pressure from architectural stress, water pressure from marine environments, or extreme pressure variations in aerospace applications can cause breakage and damage of standard annealed glass. High performance tempered glass provides an excellent alternative to ensure both durability and safety in environments where extreme pressure changes are common.

Intense Temperatures

In certain industrial environments, tempered glass is an excellent material for windows and other glass components, as it is highly resistant to temperature changes and has a higher resistance to thermal shock.

Harsh, Wet, and Extreme Environments

Heat strengthened glass is useful in applications with exposure to harsh weather conditions. With its thermal resistance and tensile strength, high performance glass is an ideal material for high winds, rain, and temperature extremes.

Explosions, Bullets, and Projectiles

Tempered glass is frequently used in the production of car windshields, industrial windows, and other applications where its impact-resistant nature is useful. In the event that tempered glass does break, it is into small pieces that are much less dangerous than typical sharp shards produced by standard glass.

The Thermal Glass Tempering Process

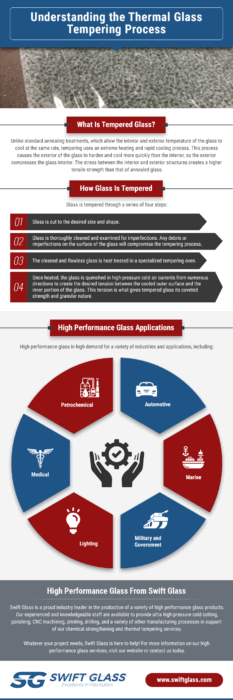

What Is Tempered Glass?

What Is Tempered Glass?

Unlike standard annealing treatments, which allow the interior and exterior temperature of the glass to cool at the same rate, tempering uses an extreme heating and rapid cooling process. This process causes the exterior of the glass to harden and cool more quickly than the interior, so the exterior compresses the glass interior. The stress between the interior and exterior structures creates a higher tensile strength than that of annealed glass.

Tempered glass is also more heat resistant, and can withstand heat up to 470°F, which could cause untreated glass to shatter or crack. The main benefit of tempering is the compression prevents the glass from breaking into jagged pieces upon impact. Rather, the glass crumbles into less dangerous rounded pebbles.

How Glass Is Tempered

Glass is tempered through a series of four steps:

- Glass is cut to the desired size and shape.

- Glass is thoroughly cleaned and examined for imperfections. Any debris or imperfections on the surface of the glass will compromise the tempering process.

- The cleaned and flawless glass is heat treated in a specialized tempering oven.

- Once heated, the glass is quenched in high-pressure cold air currents from numerous directions to create the desired tension between the cooled outer surface and the inner portion of the glass. This tension is what gives tempered glass its coveted strength and granular nature.

High Performance Glass Applications

High performance glass in high demand for a variety of industries and applications, including:

- Automotive

- Marine

- Military and Government

- Lighting

- Medical

- Petrochemical

High Performance Glass From Swift Glass

Swift Glass is a proud industry leader in the production of a variety of high performance glass products. Our experienced and knowledgeable staff are available to provide ultra high-pressure cold cutting, polishing, CNC machining, printing, drilling, and a variety of other manufacturing processes in support of our chemical strengthening and thermal tempering services.

Whatever your project needs, Swift Glass is here to help! For more information on our high performance glass services, visit our website or contact us today.

The value of high performance glass comes from its high breaking point and the manner in which it breaks. Rather than shattering into long, sharp pieces like standard annealed glass,

The value of high performance glass comes from its high breaking point and the manner in which it breaks. Rather than shattering into long, sharp pieces like standard annealed glass,