Tempered Glass 101 – A Quick Guide

Leave a CommentAs a particularly strong material, tempered glass is fabricated to provide optimal durability and safety for diverse projects. It’s applicable in everything from residential settings and consumer goods to industrial facilities and construction sites. Learn more about this versatile glass, its primary benefits, how it’s made, and its ideal applications.

What is Tempered Glass?

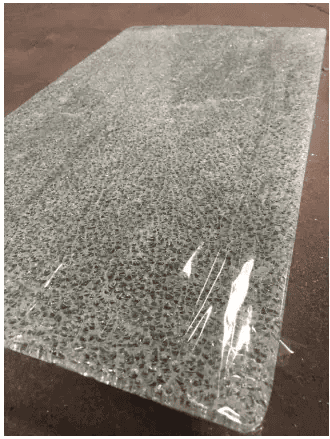

Tempered glass is a strengthened glass that’s ideal for applications in which standard annealed glass wouldn’t be sufficiently strong. Also referred to as safety glass or toughened glass, manufacturers produce this product by heat-processing the glass, resulting in a material that’s as much as four times stronger than traditional glass.

The material achieves this through a delicate balance of interior tension and surface compression, with a minimum of 10,000 psi of compressive stress. Once you temper glass, however, it’s in its final state. You can’t make any additional cuts, drill holes, add etching, or polish the glass without upsetting the mechanical stresses and potentially shattering the material.

Many industries utilize this versatile glass to create durable products that must withstand specific thermal conditions. For instance, building codes will sometimes specifically state that tempered glass must be used as it lends a higher degree of safety and protection to an application. It’s also ideal for high-contact surfaces and products for its added toughness.

Tempered Glass Properties & Benefits

Tempered glass offers numerous advantages compared to regular glass. The benefits of tempered glass include:

- Increased safety. The primary advantage of tempered glass is that, in the event that it does shatter, the glass will break into small, dull pieces. This decreases the likelihood that someone will sustain injuries from broken glass shards.

- Enhanced strength and durability. Tempered glass is significantly stronger than standard glass varieties, allowing it to hold up well against pressure and impact. It’s also resistant to everything from abrasion to chemical exposure.

- Resistance to high-heat conditions. The heat resistance of tempered glass lends it to applications in high-heat industrial equipment like windows for a furnace.

- Good clarity for optimal visibility. Regardless of application, tempered glass maintains its transparency, making it an ideal option for observation windows to monitor operations.

- Application versatility. Between its strength and its resistance properties, tempered glass is ultimately a highly versatile material option for diverse applications.

Common Tempered Glass Uses

So, what is tempered glass used for? Tempered glass is common for architectural features like windows, skylights, doors, and partitions, but it has an extensive array of uses ranging from consumer products to industrial applications. This glass type is well suited to products such as:

- High-pressure and explosion-proof windows

- Fire department access panels

- Safety door windows, space partitions, and related industrial facility features

- Protective safety guards and windows for machinery

- Glass lab equipment that can withstand both high heat and chemicals

- Transparent covers or enclosures for gauges, sight glass, and other instrumentation

- Glass walls for elevators or stairways

- Side and rear vehicle windows

- Frameless shower doors and glass walls

- Refrigerator shelving, oven door observation windows, stovetops, and appliance components

- Lighting fixtures

- Decorative panels for added aesthetic appeal in interior design

- Display cases and cabinets

- Glass tabletops

Understanding The Glass Tempering Process

But how is tempered glass made? Manufacturers create this product by heating, or tempering, the glass. The tempering procedure involves a few steps:

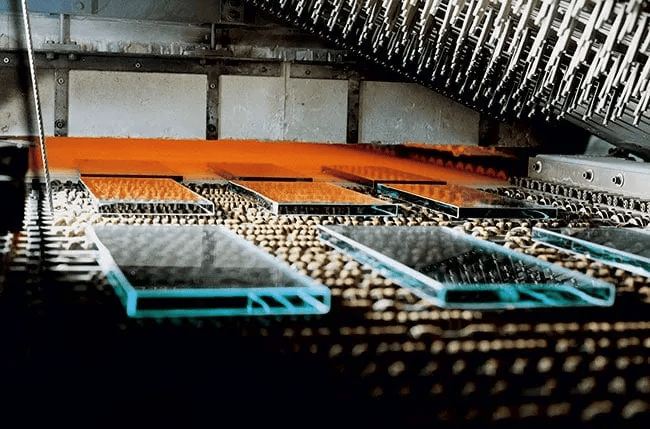

- Heating. The glass first moves through a high-heat tempering oven, which raises the temperature of the glass to approximately 1200° F as part of a highly controlled process. This temperature falls between the higher deformation temperature and the lower strain temperature of the glass.

- Quenching. After the oven sufficiently heats it, manufacturers then quench the glass, cooling it down. A very fast process, quenching involves multiple nozzles that blast the material with cool air for several seconds. This dramatic thermal shock is how tempered glass comes by its strength. The surface and edges of the material compress and the inner layer is in tension, resulting in glass that’s three to five times as strong as traditional varieties.

>> Thermal Glass Tempering vs. Chemical Strengthening: What’s the Difference?

Contact Swift Glass: Your Source for High-Quality Tempered Glass Solutions

Whether you have a small or large project, you can feel secure in the knowledge that Swift Glass offers only first-rate, carefully inspected tempered glass parts. Our expert thermal glass tempering services are of the highest quality.

In addition to our tempering capabilities, our experienced team of specialists also provides chemical strengthening, CNC machining, ultra-high-pressure cold cutting, drilling, polishing, and printing services for turnkey results.

To learn more about the advantages of tempered glass, download our eBook, “Creating Glass That Withstands Extreme Environments,” or contact us with any further questions.