Swift Glass specializes in the advanced fabrication of high-quality glass wafers for a vast range of commercial and industrial applications. Borosilicate glass wafers, in particular, are known for their high level of strength, durability, and transparency. Additionally, borosilicate provides many advantageous thermal properties at an affordable price.

We work with several leading borosilicate manufacturers, including Corning and SCHOTT, to deliver the most reliable standard and custom borosilicate glass wafers to market. Read on to learn more about the benefits and applications of borosilicate glass wafers, such as SCHOTT BOROFLOAT® Glass.

Borosilicate Glass Wafer Benefits

Borosilicate wafers provide many advantages over alternative wafer materials, such as:

- High resistance to heat and cold

- Durability against cracks and breakage, even under extreme temperature fluctuations

- Corrosion and chemical resistance

- High flatness

- Thermal shock resistance

- Adapted thermal expansion, ideal for micro-electromechanical systems (MEMS)

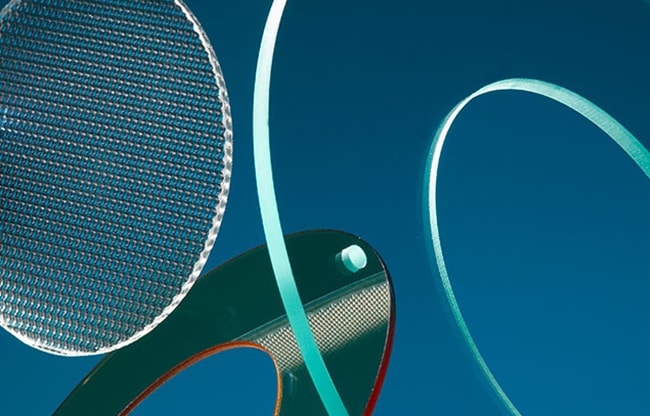

These benefits make borosilicate glass wafers a superior choice for a wide range of uses, including semiconductors and MEMS, integrated circuit (IC) packaging, biotechnology (including X-rays), microfluidic chips, and much more. As Internet of Things (IoT) technology expands, glass wafers made from advanced materials will become an even more important aspect of daily life.

Discover SCHOTT BOROFLOAT® Glass: A Floating Borosilicate Glass for Wafer Fabrication

Floating borosilicate glass offers exceptional durability in terms of mechanical strength and resistance to chemical corrosion. SCHOTT BOROFLOAT® Glass borosilicate wafers have several key advantages over silicon wafers, including very high transparency, adapted thermal expansion, and superior flatness. Their cost-effectiveness makes borosilicate wafers a popular choice for semiconductor manufacturers.

Common Applications of Borosilicate Wafers

Semiconductor manufacturers consider borosilicate ideal for bonding common semiconductor substrates, such as silicon. They’re also indispensable to MEMS, and researchers developing microfluidic chips prefer borosilicate’s high heat and chemical resistance.

Borosilicate is also very affordable, making it an excellent choice for many types of electronics. For instance, a borosilicate glass lens transmits light better than low-quality plastic lenses in flashlights and high-intensity discharge (HID) lamps. Space applications such as reflecting telescopes rely on borosilicate mirror surfaces for their thermal shock resistance and ability to resist distortion under wide temperature fluctuations.

Contact Swift Glass for Standard & Custom-Designed Borosilicate Glass Wafers

Borosilicate wafers play an indispensable role in our increasingly connected world. Swift Glass is a global leader in glass fabrication, including borosilicate wafers for today’s most advanced semiconductor technologies. To deliver the highest-quality borosilicate glass wafers to our clients, Swift Glass is ISO 9001:2015 certified and ITAR registered. Our facilities and fabrication methods also adhere to international standards, MIL-Specs, and ASTM standards.

In addition to SCHOTT BOROFLOAT® Glass, we work with polished plate glass, float glass, fused silica, and quartz. Our in-house manufacturing capabilities include:

- Thermal tempering

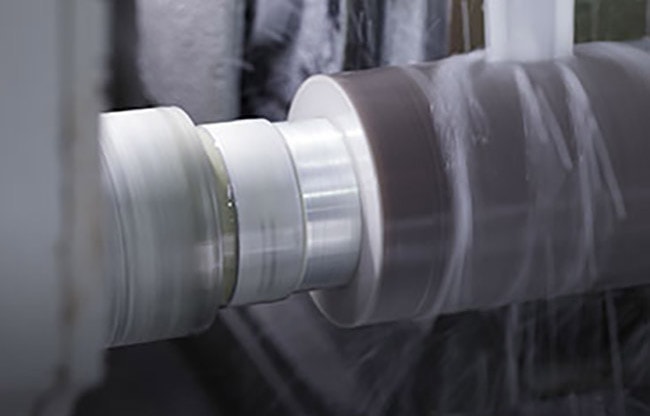

- CNC machining

- Polishing

- Drilling

- Decorating

- Silk screening

- Waterjet cutting

- Inkjet printing

- Edge grinding

- Chemical strengthening

To learn more about how our standard or custom glass wafer fabrication capabilities can meet your design goals, contact us or request a quote.