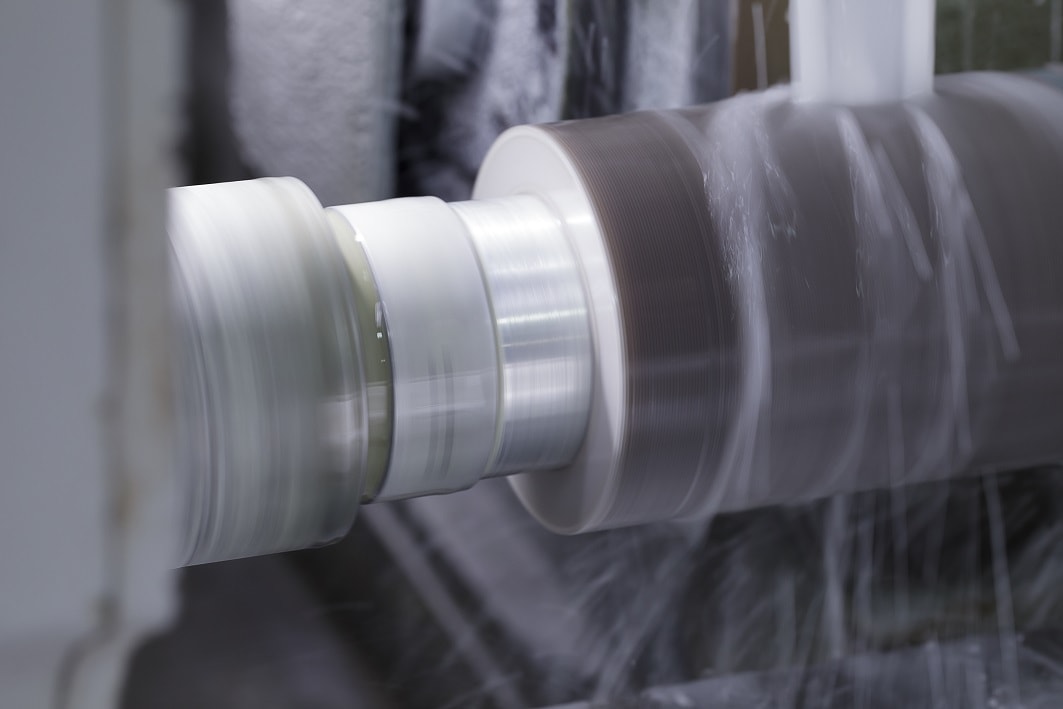

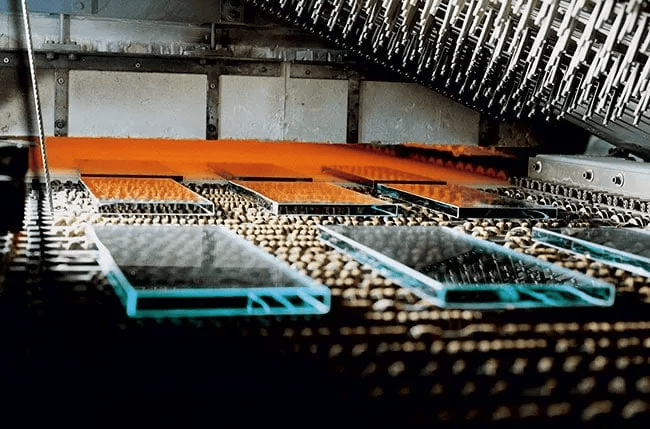

Swift Glass is an all-in-one glass fabrication provider with nearly 100 years of experience. We’re committed to providing high-quality glass services to meet diverse industry requirements. With our extensive range of glass fabrication capabilities, we can provide the solution you need no matter what challenges your project involves. You can learn more about the fabrication techniques we offer and our glass material options below.

Extensive Glass Material Selection

We work with a large variety of glass materials to meet industry-diverse needs. Our material options include:

- Borosilicate Gauge Glass Quartz

- Corning® Gorilla® Glass Low Iron Glass Clear Float Glass (Soda Lime)

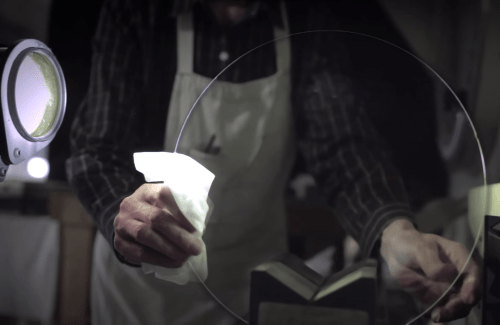

- Fused Silica Optical Color Filters Other Materials

Why Partner With Swift Glass for Your Glass Fabrication Needs?

Swift Glass brings unrivaled expertise to the glass fabrication industry. No matter how demanding your project's needs are, we have the experience and capabilities to ensure it's a success. With Swift Glass, you can experience benefits that include:

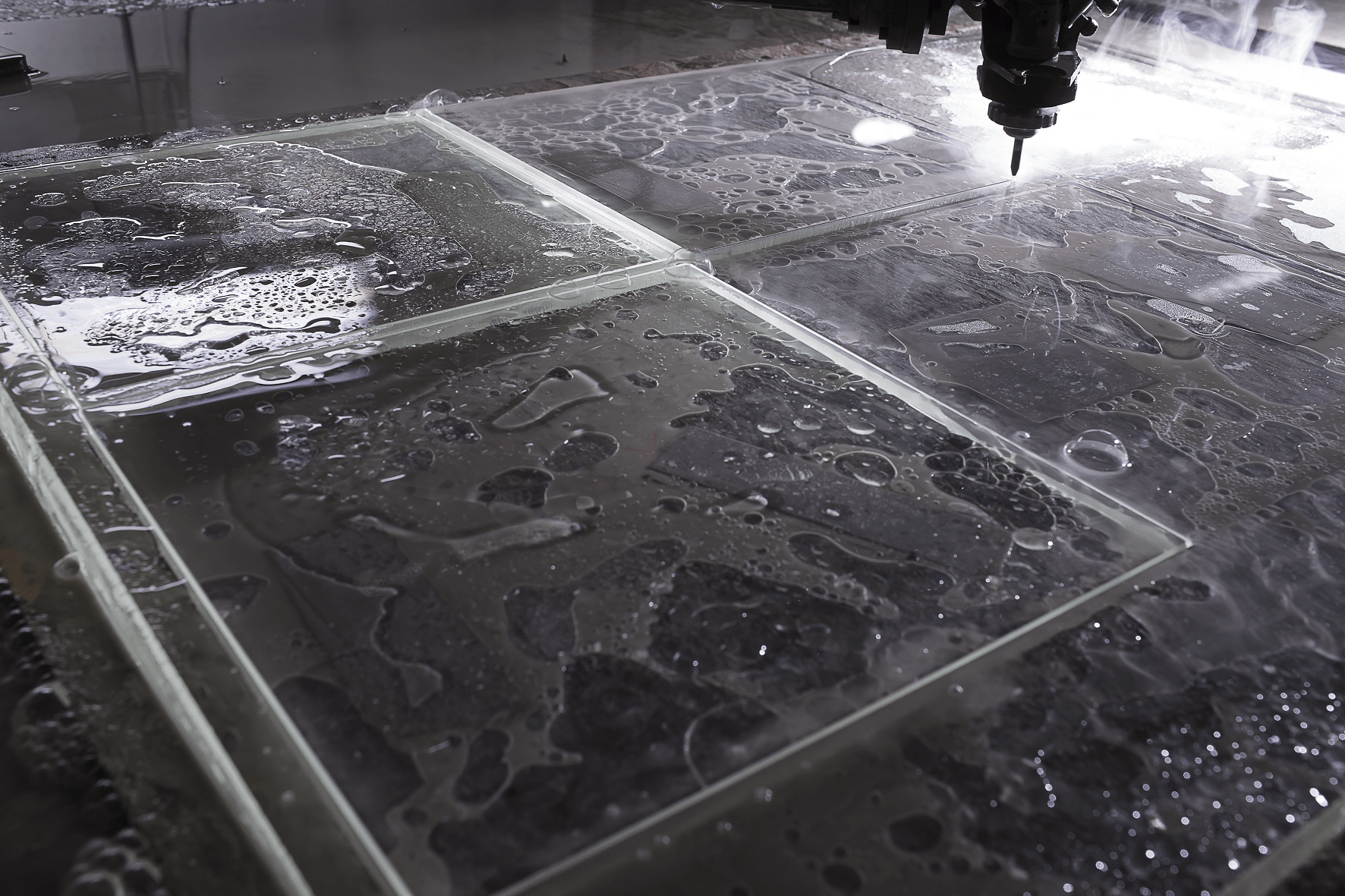

- Minimal Turnaround Times. We carry an extensive range of in-stock materials and efficiently manage all operations under one roof to ensure your project timeline requirements are met.

- Reduced Production Costs. As a one-stop shop, we’re equipped to handle every aspect of production from material sourcing to fabrication, finishing services, and inspection. Since we handle it all, you can save valuable time and money.

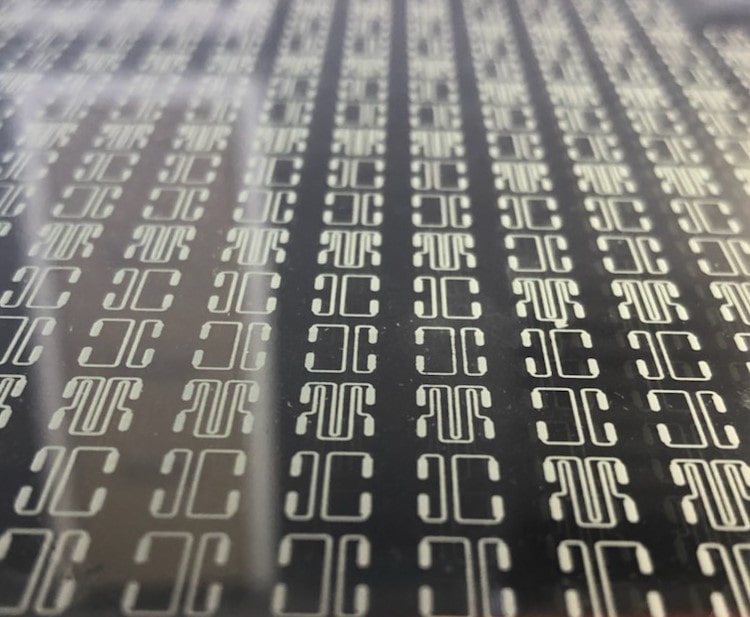

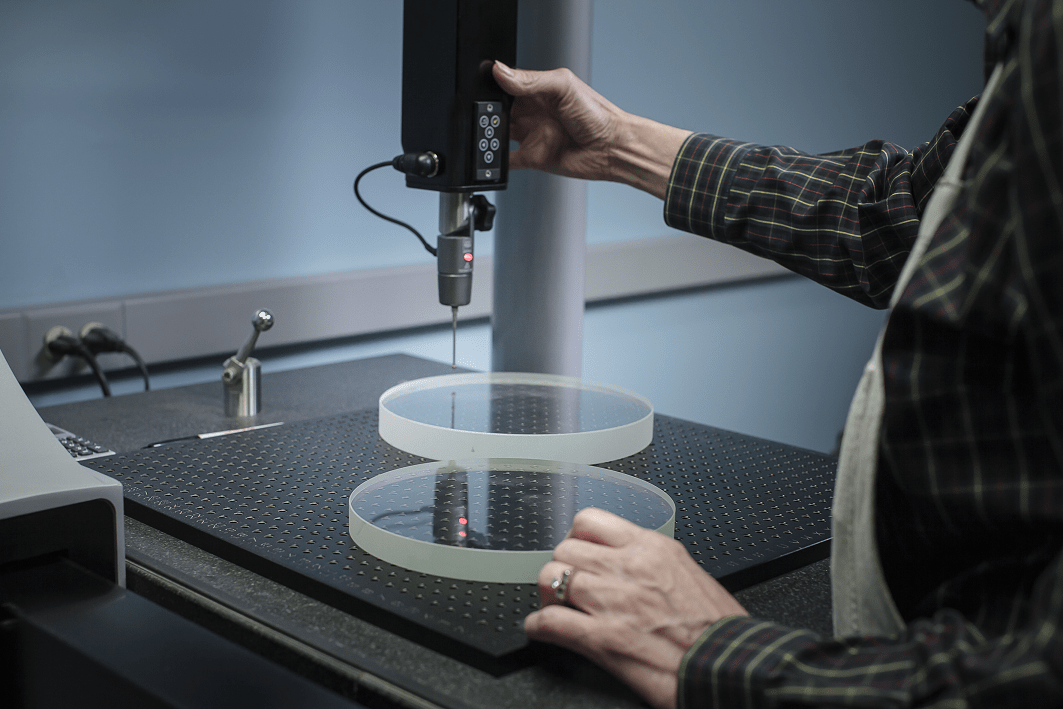

- Superior Product Quality. We’re committed to quality control and use advanced inspection equipment to ensure every part we produce fully meets your requirements.

- Adherence to Industry Standards. Swift Glass is ISO 9001:2015 certified, ITAR registered, and adheres to MIL-Specs, ASTM Standards, and International Standards.

Industries Served

Glass Fabrication Guides

Experience the Swift Glass Difference: Contact Our Glass Specialists Today

As a global leader in glass fabrication, Swift Glass has a century of experience meeting the most stringent industry requirements. No matter how demanding your application’s needs are, our team can deliver the glass components you need with a dedication to quality and precision. To get started, contact our team or request a quote today.