A flawless finish is essential in glass fabrication to improve the visual appeal and functionality of the glass product. Surface polishing can give glass components superior light transmission in optical applications, as well as other functional properties depending on the intended use.

For nearly 100 years, quality custom glass fabrication has been our specialty at Swift Glass. We are an ISO 9001:2015 certified and ITAR-registered company, committed to delivering exceptional products and services. Our recently expanded polishing center has helped us grow our manufacturing capabilities to better serve our customers’ complex glass finishing requirements.

Unmatched Glass Polishing Capabilities

With decades of industry experience and advanced manufacturing capabilities, Swift Glass has the tools and expertise to provide the ideal glass finish for all your fabrication needs. We use various polishing methods to achieve superior craftsmanship and precision with the tightest tolerances for diverse applications.

Diverse Polishing Processes

Swift Glass offers a variety of polishing processes to achieve exceptional surface quality:

- Precision grinding

- Blanchard grinding

- Surface grinding

- Contour grinding

- Optical grinding

We offer cylindrical and edge grinding as secondary polishing processes.

Finished products meet tight tolerances for installation and strict scratch-dig specifications for demanding military and small optics applications.

Serving a Myriad of Industries

Glass polishing enables glass components to meet specific standards and function reliably in a variety of industries. At Swift Glass, we can handle various glass types to fulfill the challenging requirements of the following industries:

- Aerospace

- Automotive

- Biomedical

- Energy

- Industrial

- Lighting

Precision and Control

Dimensional accuracy and smooth surfaces are essential to the functionality of glass products. Our polishing machinery is capable of flared edges, step grinding, beveling, chamfering, radiuses, and more, with a parallel and perpendicular tolerance of ±0.0005”. As a result, our customers benefit from safer handling and chip-free installations.

Technology Meets Expertise

Glass polishing requires a combination of extensive operator knowledge and advanced machinery for optimal results. Our advanced CNC operations can be combined with manual techniques to add dimensional details with accuracy and efficiency.

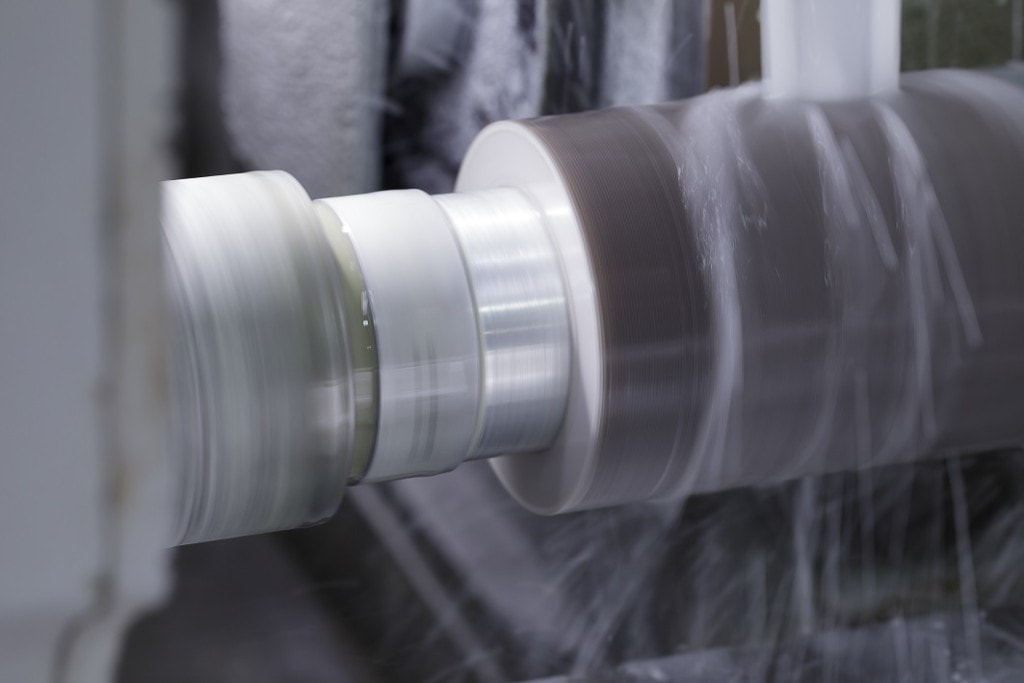

Fully Equipped Polishing Center

The recent expansion of our polishing center enhances our overall glass fabrication capabilities. The added space and new tools will help us take on larger, more complex projects and speed up turnaround times. Our new polishing center now features greater optics and polishing capabilities to better serve our customers’ needs.

Elevate Your Project with Superior Polishing: Contact Our Glass Specialists

At Swift Glass, our expanded manufacturing capabilities and industry expertise enable us to meet a range of glass polishing specifications with superior results. We stock an extensive range of materials and utilize top-of-the-line machinery to respond quickly to our customers’ needs with outstanding craftsmanship. Contact us to learn more about our polishing services, or request a free quote on your next project.

Related Glass Polishing & Finishing Content

- Glass Surface Lapping vs. Polishing

- Single-Sided vs. Double-Sided Polishing

- Scratch-Free Glass Edge Grinding & Polishing

- Surface Lapping & Polishing