In many industrial applications, glass must be polished in specific ways to achieve the correct optical properties. Glass polishing offers an ideal solution for glass components that require a high level of precision, as polishing uses very fine abrasive particles to polish surfaces to a superior finish.

The Differences Between Single-Sided vs Double-Sided Polishing

There are two types of polishing: single-sided polishing and double-sided polishing. Which type is most appropriate depends upon the specifics of the application and design.

Single-Sided Polishing

Single-sided polishing machines move one surface over the workpiece, grinding away at only the top surface while keeping the bottom surface protected. Single-sided polishing is ideal when:

- Two surfaces of the work need to be polished to different requirements

- When parts only require polishing on one side

- Polishing large parts (the workpiece can be flipped to polish the other side if necessary)

The process of polishing is quite complex, especially when the highest levels of accuracy and precision are required in the finishing of a piece. It is important for manufacturers to analyze and control the wear of the polishing surfaces. Any irregularities or worn machines can damage the finish of a piece.

Double-Sided Polishing

Double-sided polishing is performed on both sides of a piece at once. Fine abrasive particles are suspended in a liquid which is used to wear away the top and bottom surfaces of a piece of glass. Planetary action on the part of the top and bottom plates results in excellent surface finish, including:

- Transmitted wave front error

- Parallelism

- Surface quality

- Surface roughness

Because the two sides of the work piece are abraded equally, it reduces stress on the material and is ideal for most optical materials. Double-sided polishing is best when:

- Two sides of a piece must be exactly parallel and equal in finish

- Parts have very specific flatness requirements

- Design requires the highest available surface quality in factors such as parallelism and flatness

Single-Sided and Double-Sided Polishing Services with Swift Glass

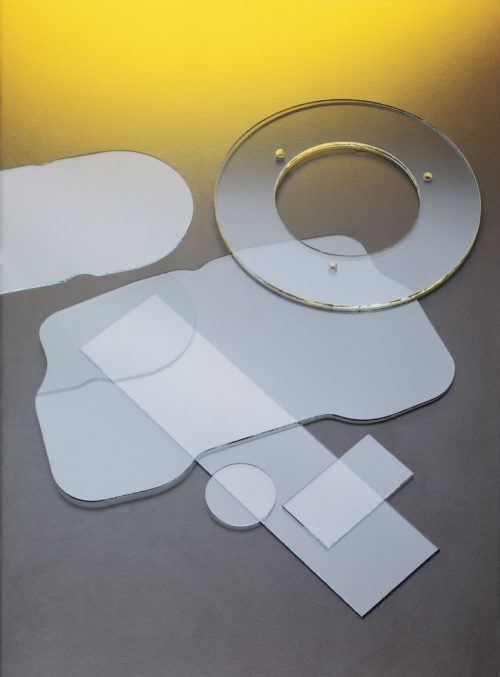

At Swift Glass, we offer both single-sided and double-sided polishing services. Precise parallelism and high flatness are important requirements for many optical applications. We offer the services to meet those needs. Swift Glass possesses capabilities for both high- and low-volume projects with a combination of manual operations and computer-controlled machinery.

Swift Glass has the services you need to achieve the correct precision and surface finish on your glass parts. We are experts in both single- and double-sided polishing and can help you determine which is correct for your application.

For more information on our polishing services, please request a quote today.