The differences between low-iron and traditional clear glass are pronounced enough that many people can’t believe what they’re seeing – or what they haven’t been – when they’re shown low-iron glass options. Traditional clear glass can be hazy and is often faintly tinted, even at its best. Color issues may arise on the edges of thicker pieces and light often isn’t allowed to truly penetrate the glass due to its chemical makeup.

Conversely, low-iron glass offers a practical solution to common problems associated with traditional clear glass. Glass that is specially manufactured to have a low iron content can shed the bulk of the color casting (tinting) that comes along with traditional glassmaking methods. This lack of color provides exceptional clarity and top-notch light transmission.

What Is Low-Iron Glass?

Low-iron glass, also known as optically clear glass, is made from silica and contains very low amounts of iron. The low iron levels serve to remove the blueish tint that’s associated with thicker traditional glass. Low-iron glass sees wide use in solar applications and is also popular in the aquarium and display industries, where clarity is valued.

Low-iron glass, also known as optically clear glass, is made from silica and contains very low amounts of iron. The low iron levels serve to remove the blueish tint that’s associated with thicker traditional glass. Low-iron glass sees wide use in solar applications and is also popular in the aquarium and display industries, where clarity is valued.

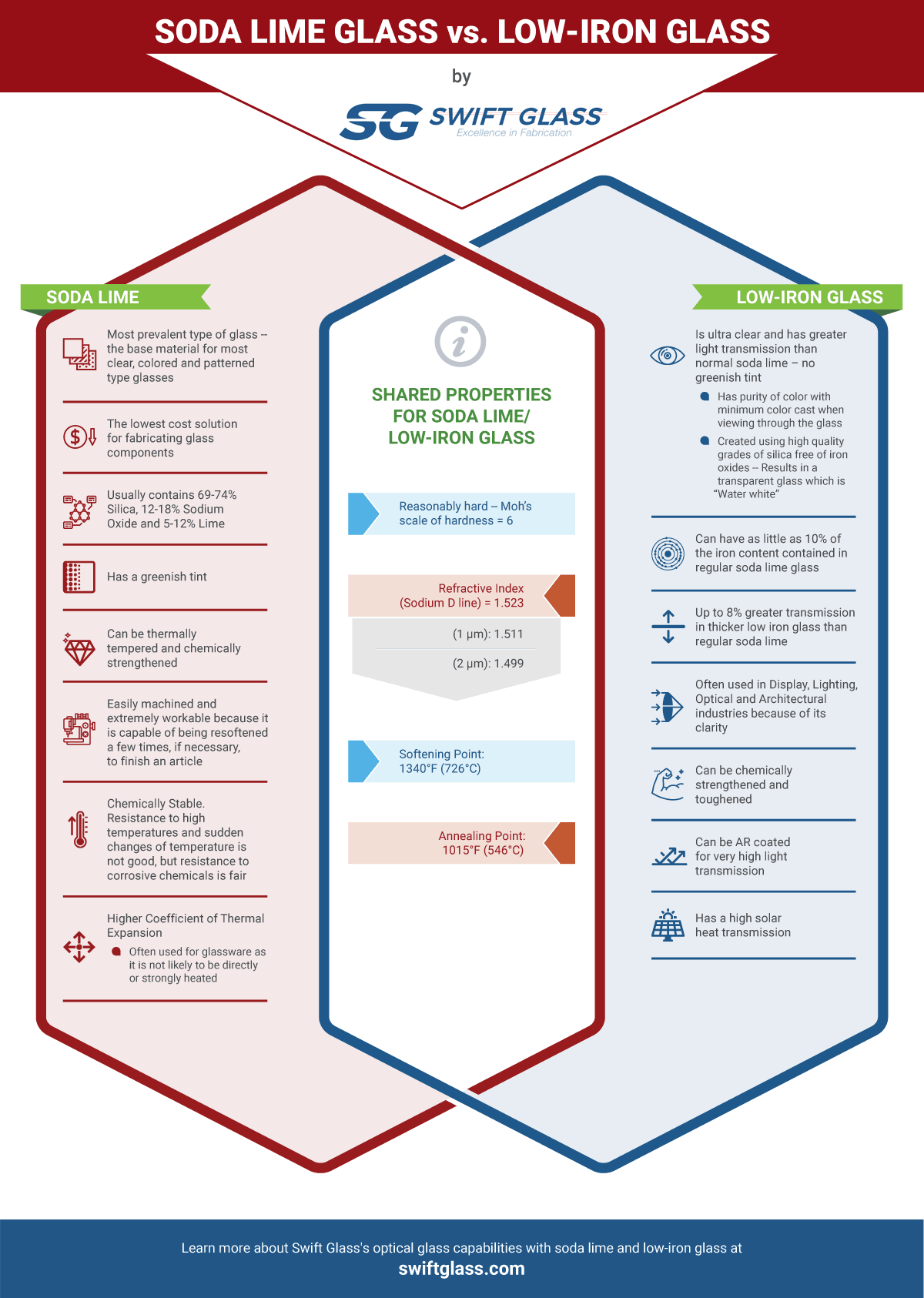

Low-iron glass usually has a ferric oxide content about ten times less than ordinary plate glass. Iron is intentionally lowered through the use of special silica sand with naturally low iron levels. This low iron content is what provides the glass with exceptional color neutrality and clarity.

Low-Iron Glass vs. Standard Clear Glass

Iron Content

Traditional glass typically has a ferric oxide content of close to 0.1%. This oxide is one of three key iron oxides of iron.

Manufacturers have managed to get ferric oxide levels down to just 0.01% in low-iron glass.

Color Tint

Standard clear glass’s higher iron content means that it has a blue-green tinge. For those looking to back-paint or coat their glass, low-iron options should not be overlooked. The green hues associated with traditional clear glass can become problematic in terms of aesthetic appeal, as the edges of thicker pieces of glass can often times appear nearly black, creating both an eyesore and color problems. This can create conflicting color problems when painting.

Low-iron glass boasts virtually no color tint. It offers individuals and businesses alike the opportunity to color-match their glass and ensure that it remains aesthetically pleasing. A clearer starting point means less work with color-matching when you need to paint your glass. While even low-iron products will continue to have a hint of color to them, it has been found that smaller pieces will generally exhibit far less tint than larger ones.

Light Transmission

Light transparency can be improved by up to 6% simply through the modification of iron content in glass. Low-iron glass provides maximum brightness and clarity with a higher visible light transmittance than traditional clear glass. Applications requiring an unrestricted view can see tremendous improvement with the use of low-iron glass over more traditional options. Low-iron glass achieves these optimum levels of clarity thanks to its iron levels; light transmission levels will virtually never dip below 90% with low-iron glass.

Light transmission is not perfect in low-iron glass, though thinner cuts of low-iron glass will boast more impressive light transmission levels than those that are thicker. One should also consider that between two cuts identical in thickness; however, low-iron glass will always win out over traditional clear glass in terms of light transmission.

Low-Iron Glass Solutions from Swift Glass

At Swift Glass, our experts will guide you through the process of selecting an appropriate low-iron glass solution for your home or your business. For a wide range of applications, low-iron options are the superior choice for those in need of clarity.

If you’re interested in incorporating low-iron glass into your personal or business endeavors, feel free to contact us for more information or to learn more about our optical display glass materials.