Sight Glasses for Oil & Gas Industry Applications

Sight glasses—also referred to as viewing glasses—are window elements that are installed in equipment to facilitate the observation of internal processes while maintaining the safety of the observer and the functional integrity of the system. The visibility offered by these components allows equipment operators to analyze ongoing processes and make better-informed adjustments to improve process quality. They play a critical role in many industrial operations, including chemical manufacturing, food processing, pharmaceutical production, and oil and gas extraction and refinement.

Sight glasses—also referred to as viewing glasses—are window elements that are installed in equipment to facilitate the observation of internal processes while maintaining the safety of the observer and the functional integrity of the system. The visibility offered by these components allows equipment operators to analyze ongoing processes and make better-informed adjustments to improve process quality. They play a critical role in many industrial operations, including chemical manufacturing, food processing, pharmaceutical production, and oil and gas extraction and refinement.

Below we outline the types of sight glasses employed in oil and gas industry applications and key considerations when choosing one for a given situation.

Types of Sight Glasses for the Oil & Gas Industry

The term “sight glass” encompasses several different products that allow for the observation of processes inside of equipment, including:

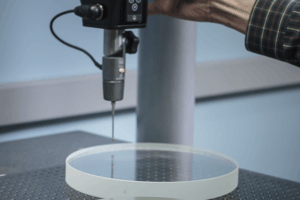

- Circular sight glass windows. Sight glass windows enable observation of internal processes. They generally feature a circular design to prevent image distortion and facilitate even stress distribution.

- Liquid level gauges. Sight glasses in the form of liquid level gauges are used to observe the level of fluid in drums, tanks, pressure vessels, and other containers without disrupting the containment space.

- Sight glass flow indicators. Sight flow indicators allow operators to monitor the direction and speed of fluid movement through a pipe or conduit.

Selection Considerations for High-Pressure Sight Glasses

Sight glasses allow operators to observe processes safely while they are in progress, which is particularly useful in applications involving high pressures or temperatures. Having a line of sight into the equipment enables them to ensure the system is working properly, the material is flowing or processing correctly, and the dust and debris are not clogging the system. However, achieving these functions necessitates choosing the right sight glass for the application.

Sight glasses allow operators to observe processes safely while they are in progress, which is particularly useful in applications involving high pressures or temperatures. Having a line of sight into the equipment enables them to ensure the system is working properly, the material is flowing or processing correctly, and the dust and debris are not clogging the system. However, achieving these functions necessitates choosing the right sight glass for the application.

When selecting a sight glass, some of the key factors to consider are:

- Pressure: the amount of pressure the glass will regularly be exposed to during normal operation

- Risk of impact damage: whether the glass will be subject to impacts and vibrations

- Process fluids: the types of fluids used in the equipment and their characteristics (e.g., are they abrasive or corrosive?)

- Operating temperatures: the highest and lowest operating temperatures and typical fluctuations

- Maintenance and handling requirements: the frequency of maintenance and handling operations

Knowing each of these factors helps determine the composition, shape, size, and installation method of the ideal sight glass for an application. Since sight glasses are often used for critical and volatile operations, they must be able to withstand the conditions—including pressure, temperature, and chemical exposure—experienced during use. Tempering and reinforcing the glass can reduce the risk of damage and failure.

Specialized Sight Glass Solutions From Swift Glass

At Swift Glass, we are proud to be one of the oldest glass tempering companies in the United States. Since 1966, we have provided high-quality tempered glass products to customers across a wide range of industries, including the oil and gas sector. Our glass tempering capabilities ensure the sight glass components used in the industry’s equipment remain reliable even when exposed to super high or fluctuating pressures.

For additional information about our sight glass capabilities and how we serve the oil and gas industry, check out our helpful guide, Selecting and Maintaining Sight Glass.