Category Archive: Glass Tempering

In the petroleum and natural gas mining industry, well completion is critical to safe and efficient production with hydraulic fracturing. A wellbore is mined in sections or zones, and previous zones must be properly blocked before extraction can begin on the next one. Devices called well plugs, fracking plugs, or frac plugs, are used to block and isolate zones. Traditionally these plugs are placed during production and removed later when extraction is finished. Unfortunately, this often requires time-consuming and expensive retrieval operations, posing safety risks to the personnel involved.

A groundbreaking solution is shatterable glass well plugs made with tempered glass. Keep reading to learn how these controlled-shatter glass well plugs work and why they can revolutionize well completion operations.

Introducing Temporary Glass Well Plugs

Well plugs are used to isolate zones within a wellbore to block sections that have already been mined from subsequent sections. Plugs are often cylindrical and expand to form a secure circumferential seal with the wellbore casing. Inserted in the plug is an additional component that closes the inner diameter opening. This prevents a loss of pressure while fluids are pumped.

Traditional plugs must be removed when extraction is finished. This process is labor-intensive, contributes to production downtime, and can be hazardous to workers.

The alternative is shatterable plugs, which do not need to be removed. Instead, they are made from materials that are tough enough to withstand high-pressure situations, yet designed to completely break down and shatter within a designated pressure range.

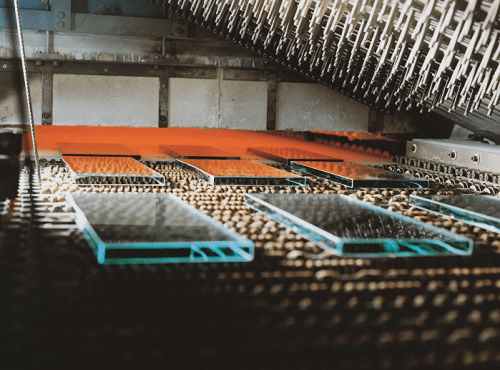

Tempered glass can be used as an effective plug material. Swift Glass has developed very high tempered glass temporary plugs that disintegrate into a fine powder. These plugs can be used in various wellbore configurations, including horizontal and at angles, and they do not need to be removed, simplifying well cleanup.

How Tempering Makes Temporary Glass Well Plugs Possible

Tempered glass is an ideal material for plugs because it resists thermal shock, corrosion, and impact. This inherent durability is needed to withstand harsh conditions in the wellbore during operations.

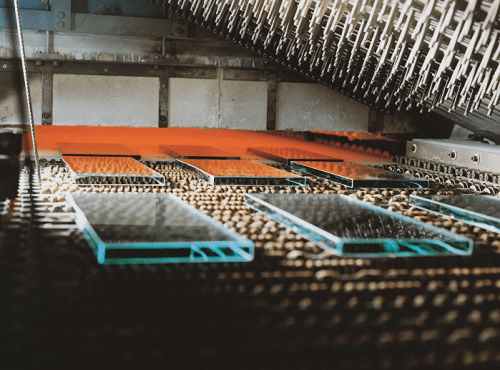

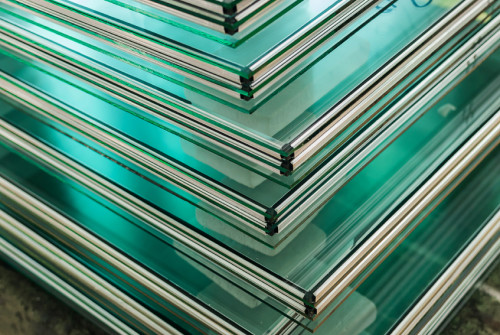

The tempering process involves heating the glass to high temperatures and then rapidly cooling it, creating a unique stress distribution within the material. This strengthens the glass so it can be used in demanding applications, including well completion.

Tempered glass plugs provide excellent control over zone isolation and well completion applications because they can be shattered on command. When intentionally ruptured in this way, the tempered glass in these plugs breaks down in a controlled manner. The internal stress distribution causes the glass to shatter into small, blunt fragments, which then disintegrate into powder. This characteristic “dicing” pattern guarantees that the disintegration is predictable and safe, providing a reliable solution for zone isolation without the complications of retrieval.

The Benefits of Tempered Glass for Well Plugs

Tempered glass offers several significant advantages for fracking plugs:

- Strength and durability: The tempering process helps glass withstand the harsh conditions of well completion for reliable performance throughout the operation.

- Controlled disintegration: The predictable breakdown of tempered glass when intentionally ruptured allows for better control over the well completion process.

- Safety: Dissolvable frac plugs eliminate the risks associated with removable plugs, leading to safer working conditions and reduced downtime.

Revolutionize Your Well Completion Process: Contact Swift Glass Today

Swift Glass’s high tempered glass for dissolvable frac plugs is a significant advance in well completion technology. Our tempering process results in high-quality glass that addresses the limitations of traditional frac plugs, offering a safer, more efficient, and versatile solution.

We specialize in a range of glass materials and products tailored to your application. In addition to tempered glass, our capabilities include on-site CNC machining, bending, chemical strengthening, waterjet cutting, polishing, edge grinding, and drilling. We are also ISO 9001:2015 and ITAR certified. Learn more about our services and company history.

Contact Swift Glass today to learn more about controlled-shatter frac plugs made with highly tempered glass, or request a quote to get started.

Mining equipment must function seamlessly amid extreme conditions. The choice of materials can significantly impact project safety, productivity, and efficiency. For example, tempered glass must be used instead of annealed glass for certain applications because tempered glass can withstand the high temperatures and corrosive conditions of mining environments. Swift Glass delivers high-quality tempered glass solutions tailored to the mining industry’s unique needs.

Discover the benefits of tempered glass and how our products are utilized in the mining industry.

Elevate Your Mining Operations: The Benefits of Tempered Glass

Temperature Resistance

Mining equipment is exposed to a wide range of temperatures, from the intense heat of machinery to cold storage areas. Tempered glass, such as the tempered glass barrier plugs we produce, excels in these extreme conditions, maintaining its integrity and functionality amid temperature fluctuations. This temperature resistance is vital for applications such as lighting fixtures and enclosures, ensuring they perform reliably in any environment.

Safety

The safety benefits of tempered glass over annealed glass are important. When tempered glass does break, it shatters into small, blunt pieces that are far less likely to cause injury. This safety feature is particularly important in mining, where the risk of injury is heightened. Our tempered glass plugs are tempered in an oven to a certain strength level so that, when operating pressures surpass a specific limit, they break apart as needed. Other applications like machine windows and control panels become safer with tempered glass, protecting workers and equipment alike.

Durability

Thermal tempering enhances the glass’s strength, thermal shock resistance, and impact resistance. This durability is essential for mining equipment, which is exposed to abrasive materials, heavy loads, and sudden temperature changes. By improving the durability of glass components, mining operations can reduce downtime and maintenance costs.

The Swift Glass Advantage

Why choose Swift Glass for your mining glass needs? Our expertise in thermal glass tempering sets us apart. We are an ISO 9001:2015 certified and ITAR-registered company, adhering to strict mining industry standards. With nearly a century of experience in glass fabrication, Swift Glass is a global leader in providing innovative glass solutions to industries from aerospace to biomedical to optical to mining. In addition to thermal tempering, we provide a range of additional capabilities:

Swift Glass offers a range of thermal glass tempering capabilities, designed to meet the diverse needs of the mining industry. We can handle large sizes, custom shapes, and specialized coatings, ensuring that each piece of tempered glass is perfectly suited to its intended application. Swift Glass provides solutions for heavy machinery, protective windows, barrier plugs, and other mining applications.

Additional Resources

Click one of the eBooks below to learn more about the different types of glass we offer.

Contact Swift Glass: Your Reliable Partner in Mining Glass Solutions

In mining, selecting the right materials ensures operational efficiency, personnel safety, and equipment longevity. Tempered glass, renowned for its exceptional durability, enhanced safety features, and remarkable temperature resistance, is the superior choice for a wide range of mining applications. Swift Glass offers tempered glass solutions designed and engineered to meet the mining industry’s stringent requirements.

Contact us today or get a free quote to learn how our thermal glass tempering solutions can benefit your mining operations.

Tempered glass is one of the most popular choices for applications in which traditional, or annealed, glass may pose a safety hazard.

For nearly 100 years, Swift Glass has been providing quality custom glass fabrication services for a wide range of industries. To provide insight on the thermal glass tempering process and its various benefits, our experts have provided answers to some of the most common questions we field here.

Check out the FAQs below.

High-intensity industrial processes call for durable equipment that will prove resistant in the face of even the toughest of applications.

If you’re carrying out procedures against harsh or extreme conditions, it’s essential that your application is equipped with the proper glass component. Tempered safety glass in windshields, for example, provides extra security in the event of breakage.

If you’re carrying out procedures against harsh or extreme conditions, it’s essential that your application is equipped with the proper glass component. Tempered safety glass in windshields, for example, provides extra security in the event of breakage.

High performance glass is required to withstand a vast range of pressures, elements, and external factors, each of which vary by industry. When operating in high intensity environments susceptible to extraneous factors, it’s important to be aware of common concerns that can arise.

Below are a few common risks associated with extreme industrial climates, along with the glass strengthening solutions that help reduce those risks:

High-Pressure Exposure

One of the most frequently noted stress points for high performance glass, this can manifest itself in marine, architectural, and even aeronautical environments.

Strengthened glass, however, can help prevent or reduce the adverse effects of high pressure. In addition, strengthened glass helps shield your work environment from harm caused by explosions, bullets, and projectile aftermath, each of which may pose a threat to safety and productivity. Safety glass offerings, like tempering, can help to ensure a less devastating effect upon impact than with regular glass.

Extreme Temperatures

Exposure to extreme temperatures can result in potentially adverse effects upon operations. Fortunately, heat-treated glasses can offer dramatically increased protection against hazards like thermal shock. Heat treatment offers glass—a material often susceptible to high temperatures—increased protection against high-temperature breakage.

Harsh Environments

Exposure to intense, abrasive elements or harsh, wet and extreme environments holds the potential to work against high performance glass. For certain extreme or outdoor environments, heat-tempered glass may not be necessary, but it can provide exceptional resistance against thermal stresses and extreme wind pressure. Fully tempered glass, however, can offer unparalleled safety when it comes to ensuring safety break pattern. If operations are under harsh weather conditions, tempered glass ensures your work environment remains both active and safe.

Learn More in Our eBook

At Swift Glass, we’re dedicated to providing consumers with the high quality materials they need for safe, efficient, and effective day-to-day procedures. For additional information regarding glass strengthening solutions, access our new eBook titled Creating Glass That Withstands Extreme Environments.

We interact with glass every day — we look through it, drink from it, and it helps us see clearly.

But not all glass is the same, and our ability to modify glass and improve its qualities is what allows us to use glass in applications where it would have been a safety hazard.

But not all glass is the same, and our ability to modify glass and improve its qualities is what allows us to use glass in applications where it would have been a safety hazard.

This modification process is referred to as glass tempering. Tempering is achieved through a thermal process. Chemical strengthening is achieved through an exchange path.

The heat tempering process involves subjecting glass to very high temperatures and then cooling it quickly. During chemical strengthening, chemicals applied to the glass change the surface to create compression.

In both instances, the outer surface of the glass is altered so that it has a higher compression than the interior glass which is in a state of tension.

This specialized glass has allowed industries to use strengthened glass in a wide variety of applications, as it delivers a variety of benefits:

- Safety

Tempered glass does not break apart and shatter as ordinary glass does. If the glass is broken, it will break into circular and small pieces and not sharp jagged shards that could cause harm. It is also easier and safer to clean up broken tempered glass without causing additional injury. Because of this it is widely used in high-pressure and explosion proof windows, lighting products, and doors for industrial and residential applications.

- Durability

The tempering process changes the composition of the glass giving it strength, durability, and scratch resistance. Tempering allows thin glass products to withstand harsh environmental conditions without losing their functionality. In medical, semiconductor, and energy applications, tempering enables glass to be successfully incorporated without fear of component failure.

- Temperature resistance

Its ability to withstand temperature fluctuations makes tempered glass suitable for aerospace and aviation applications, laboratory equipment, and household items. The ability to withstand high temperature and variations in temperatures makes this glass ideal for use in buildings to meet fire code regulations, fire engines, appliances, drinking glasses, cookware, and laboratory glassware.

Swift Glass is a leader in manufacturing tempered and strengthened glass for a wide range of industries and applications. Our extensive material selection includes float glass, Pyrex®, and Borofloat®.

Visit our website for more information about Swift Glass’s thermal glass tempering and chemical glass strengthening processes.

If you’re carrying out procedures against harsh or extreme conditions, it’s essential that your application is equipped with the proper glass component. Tempered safety glass in windshields, for example, provides extra security in the event of breakage.

If you’re carrying out procedures against harsh or extreme conditions, it’s essential that your application is equipped with the proper glass component. Tempered safety glass in windshields, for example, provides extra security in the event of breakage.

But not all glass is the same, and our ability to modify glass and improve its qualities is what allows us to use glass in applications where it would have been a safety hazard.

But not all glass is the same, and our ability to modify glass and improve its qualities is what allows us to use glass in applications where it would have been a safety hazard.