For almost 100 years, Swift Glass has fabricated quality glass materials for customers in the aerospace, optical, lighting, industrial, military, medical, petrochemical, and photonics industries. We understand the importance of meeting industry standards for clients in all industries, especially for those in the optical industry.

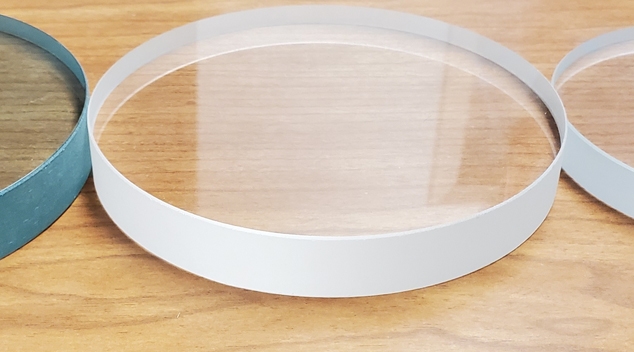

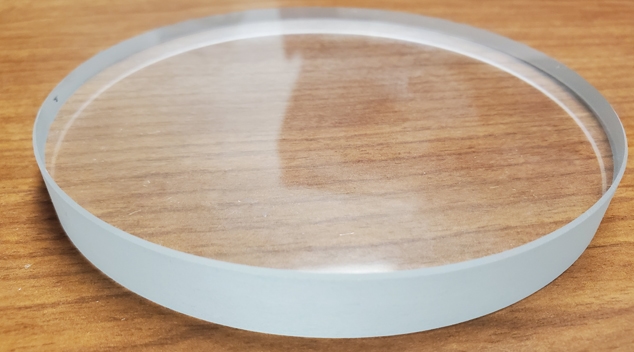

Optical glass is a subset of glass designed for lenses, beam splitters, prisms, optical windows, and other optical components. The chemical and physical composition of optical glass determines how well it transmits or disperses light. Performance is the priority for optical applications, which can be complex and demanding. That’s why we provide full-service precision optical glass fabrication services for high-volume projects that require quick turnarounds.

Industry Requirements

Optical glass must meet specific requirements to be used in applications involving the properties and motion of light. Lenses, flat optics, prisms, and lasers all need glass with special properties to operate as they should. Optical glass is made up of distinct chemical, mechanical and optical properties.

Chemical Properties

The differences in the chemical composition of optical glass are what allow different wavelengths of light to be absorbed, transmitted, or refracted, depending on what is needed for a particular application. To manipulate light within certain wavelengths, the glass may contain a combination of these additives:

- Lead

- Fluorite

- Boric oxide

- Zinc oxide

- Barium oxide

Mechanical Properties

The three mechanical properties that optical glass prioritize are transparency, purity, and hardness. Optical glass tends to have a higher density than other types of glass, with flint glass being denser than crown glass.

Optical Properties

Calculations of an optical glass’s density are known as the refractive index and the Abbe value. The Abbe value indicates the glass’s level of chromatic dispersion—the speed at which different wavelengths pass through the glass. Abbe values above 55 indicate a lower chromatic dispersion.

The refractive index measures the amount of light that is refracted—or slowed and bent—as it passes through the glass. An Abbe number lower than 50 is considered a high refractive index and indicates more chromatic distortion.

When we fabricate optical glass, we adhere to the unique standards of its intended application. Doing so will ensure quality, high performance, cost-effectiveness, and efficiency. With every project, we take the following optical glass features into consideration:

- Surface quality

- Surface flatness

- Power

- Irregularity

- Surface finish

For imaging and laser systems, Swift Glass offers scratch-dig specifications to 20-10 and sizes from ¼” diameters to 36” squares. As an ISO 9001:2015 and ITAR certified company, we have the expertise and quality control processes in place to guarantee our customers get superior, high-quality optical products every time.

The 6 Ways Light Travels Through Glass

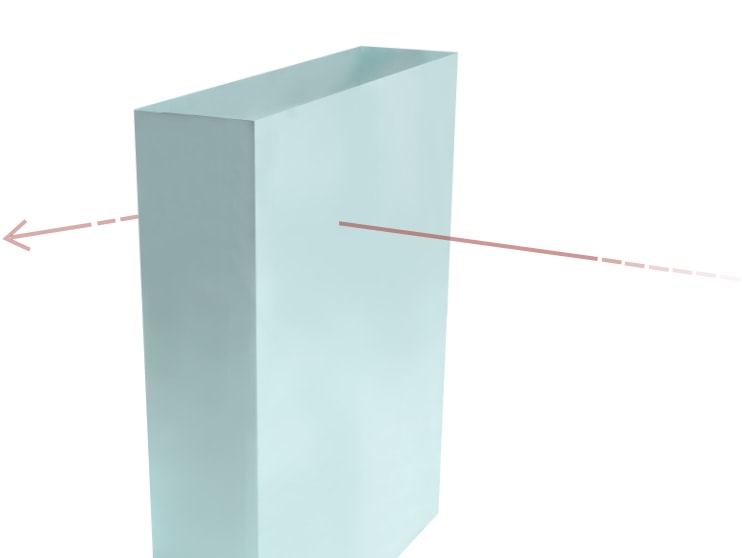

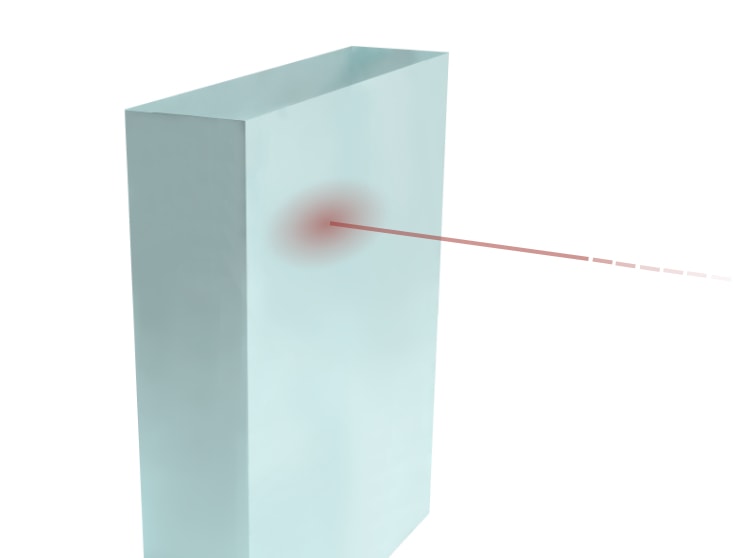

Transmission

Occurs when light travels through glass without being reflected, absorbed or scattered.

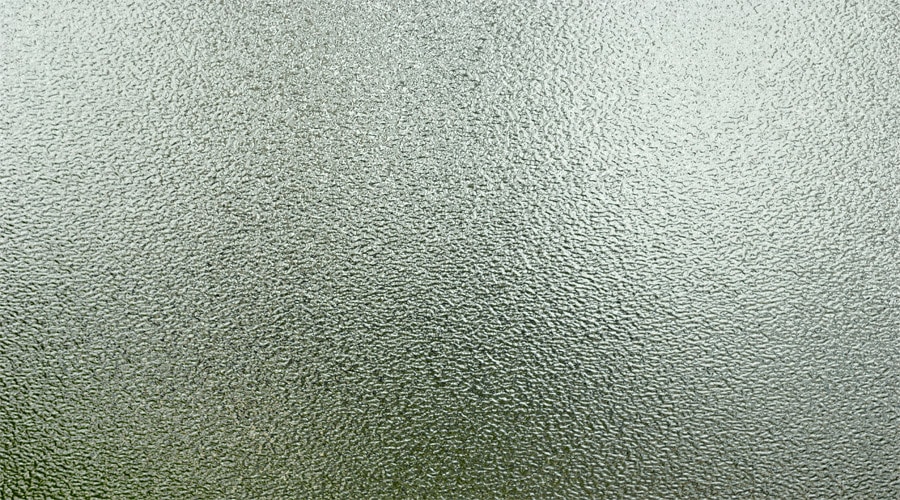

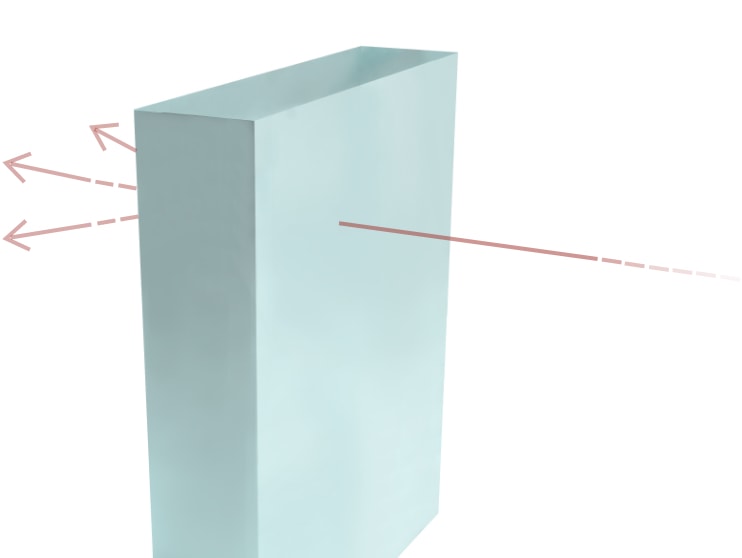

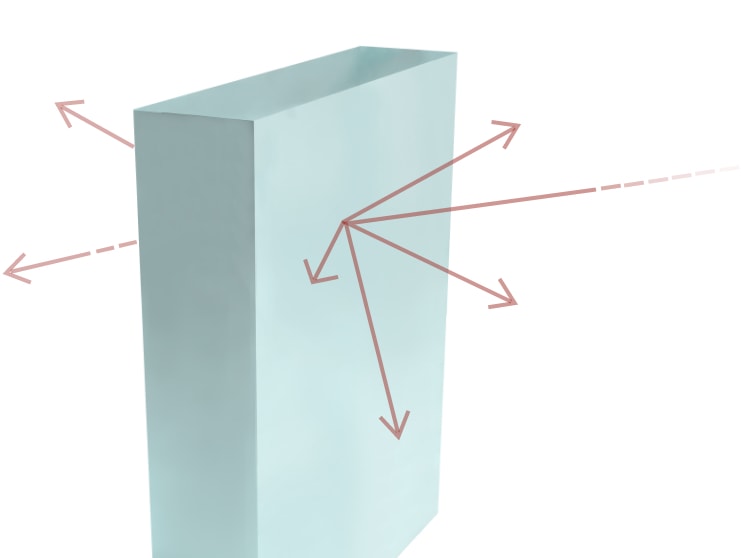

Reflection

Occurs when incoming light hits the glass and bounces off.

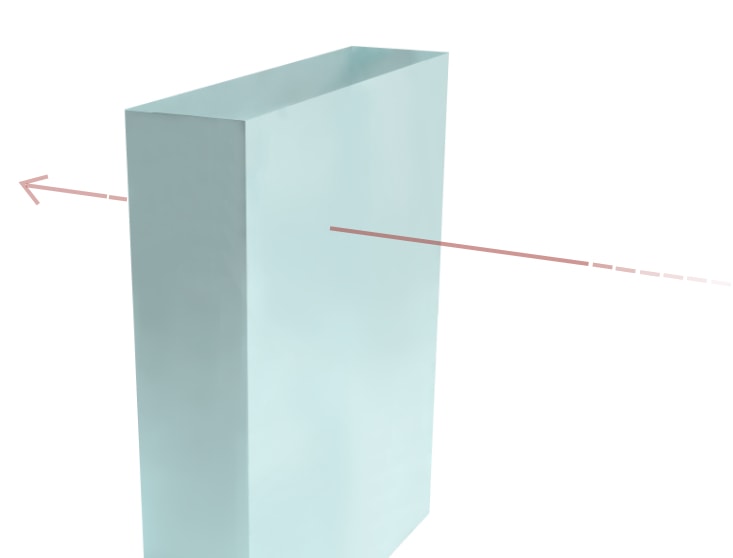

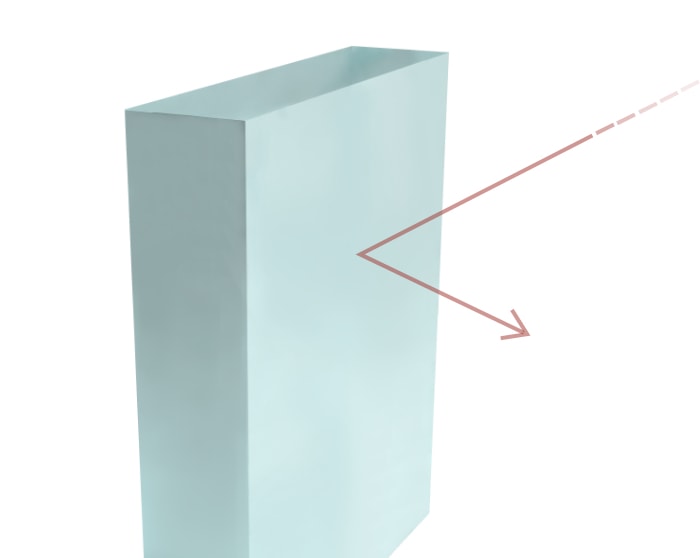

Refraction

Occurs when light waves change direction as they pass from one medium to another.

Diffraction

Refers to the bending and spreading of waves around the glass.

Absorption

Occurs when photons from light hit atoms and molecules and cause them to vibrate, creating thermal energy.

Scattering

Occurs when light bounces off of the glass in a variety of directions.

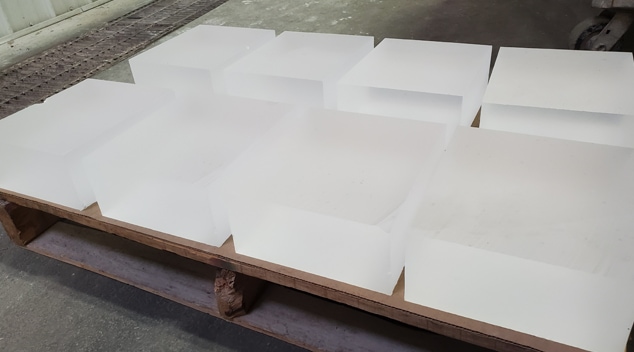

Types of Glass Materials

Swift Glass has experience manufacturing custom optical wedges, precision optical components, lenses, and optical tools. These are some of the materials we have available for a variety of optical glass needs:

- Borosilicate

- Corning® Gorilla® Glass

- Fused silica

- Gauge glass

- Low iron glass

- Optical color filters

- Quartz

- Clear float glass (soda lime)

- Others

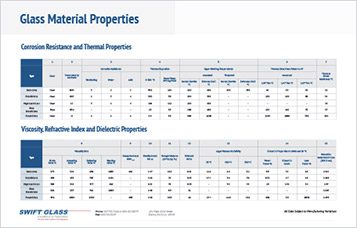

Is Your Glass Material Suitable for Your Application?

Find out with our Glass Material Properties chart.

Understanding your glass material’s thermal, chemical and physical properties is critical to ensure it can withstand the application’s use and environment.

Tolerances — A Range of Possibilities

We have the capability of working within multiple tolerances. The following is a list of typical tolerance and specification ranges we currently provide:

| Diameter | Within .001” |

| Flatness | ¼ wave |

| Parallelism | .0001” – .0005” |

| Surface Finish | 20/10 – 60/40 |

| Specification | Specification |

|---|---|

| Diameter: | .100” – 28” |

| Thickness | .007” – 3.5” |

| Rectangle Sizes | .042” – 36” |

Optical Glass Fabrication at Swift Glass

For nearly a century, Swift Glass has been a trusted fabricator of optical glass and other specialized glass components. We partner with top glass manufacturers like SCHOTT, Corning, GE, and Auer to bring our customers the very best optical glass products. Contact us to learn more about our products and services, or request a quote to get started on your project.