The term “glass fabrication” encompasses all of the processes used to work or treat raw glass material to turn it into a functional component or product. Examples include cutting, grinding, drilling, polishing, tempering, finishing, and edging. In all of these processes, precision and quality are paramount. For this reason, fabricators often use computer numerical control (CNC) machines during glass fabrication operations. This equipment enables them to customize the materials provided by glass manufacturers to precisely and accurately accommodate the specifications provided by the purchasing agent.

At Swift Glass, we are a premier glass fabricator of high-quality glass parts. Armed with almost 100 years of glass fabrication experience, state-of-the-art manufacturing equipment, and a broad selection of glass materials, our team has the knowledge, skills, and tools necessary to accommodate nearly any glass part need. Our extensive glass fabrication capabilities ensure we can complete all steps of customer projects under one roof.

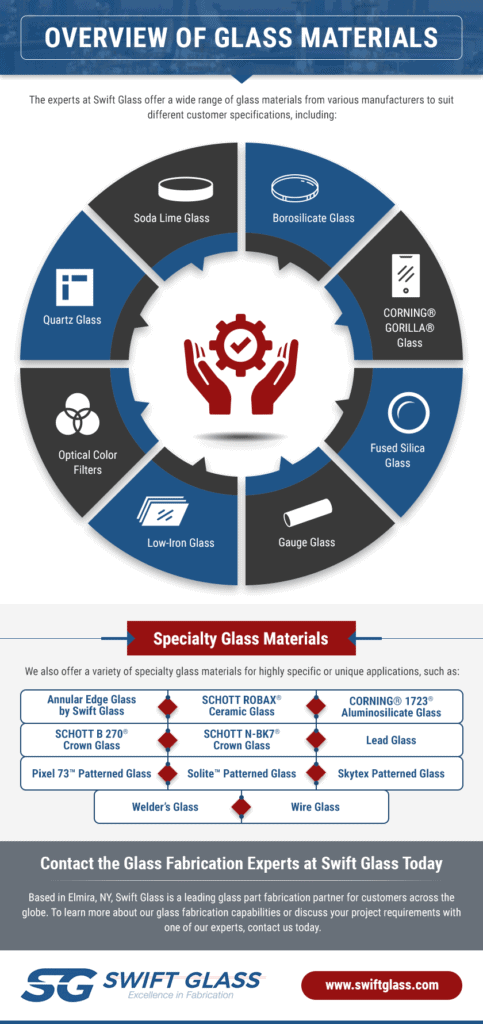

Overview of Glass Materials

The experts at Swift Glass offer a wide range of glass materials from various manufacturers to suit different customer specifications, including:

Borosilicate Glass: This material is characterized by its durability, heat resistance, chemical resistance, and thermal shock resistance. We stock the following varieties:

Borosilicate Glass: This material is characterized by its durability, heat resistance, chemical resistance, and thermal shock resistance. We stock the following varieties:

- CORNING® EAGLE 2000®

- CORNING EAGLE XG®

- SCHOTT BOROFLOAT® 33

- SCHOTT D263®

- SCHOTT SUPREMAX®

- CORNING® GORILLA® Glass: This material is known for its toughness, durability (such as its resistance to scratches and other similar damage), and aesthetic quality.

- Fused Silica Glass: This material exhibits excellent thermal shock resistance, good UV transparency, and minimal thermal expansion properties. We supply industrial, commercial, and UV-fused varieties, including the following:

- CORNING® HPFS® 7980 Industrial Grade

- CORNING® HPFS® 7980 UV Grade

- Gauge Glass: This material is a transparent tube used to monitor liquid levels in We offer these varieties:

- Standard Gauge Glass

- High Pressure Gauge Glass

- Redline Gauge Glass

- Heavy Wall Gauge Glass

- Heavy Wall Redline Gauge Glass

- MAXOS® Type A Transparent Gauge Glass

- MAXOS® Type A High Pressure Gauge Glass

- MAXOS® Type B Reflex Gauge Glass

- Gaskets

- Oil Cup Glass

- Glass Cylinders/Rods/Tubes

- Low-Iron Glass: This material is also known as optically clear glass. It is made from silica and has a low iron content, which eliminates the blueish tinting common in traditional glass. Our low-iron glass offerings include:

- SGG Diamant®

- Vitro Starphire®

- Pilkington Optiwhite™

- Optical Color Filters: These materials transmit and block particular wavelengths or ranges of wavelengths depending on their design. We supply the following types:

- HOYA

- Kopp

- SCHOTT

- Quartz Glass: This material is used for applications with high chemical purity, temperature resistance, or dimensional tolerance requirements. Our quartz glass offerings include:

- GE® 124

- Heraeus TSC-3®

- Soda Lime Glass: This material is characterized by its ability to be softened and melted over and over. We offer the following varieties:

- Guardian

- Vitro (formerly PPG) Clear Float Glass

- Vitro (formerly PPG) Solargray® Glass

- LimeX by Swift Glass

In addition to these standard glass materials, we also offer a variety of specialty glass materials for highly specific or unique applications, such as:

- Annular Edge Glass by Swift Glass

- SCHOTT ROBAX® Ceramic Glass

- CORNING® 1723® Aluminosilicate Glass

- SCHOTT B 270® Crown Glass

- SCHOTT N-BK7® Crown Glass

- Lead Glass

- Pixel 73™ Patterned Glass

- Solite™ Patterned Glass

- Skytex Patterned Glass

- Welder’s Glass

- Wire Glass

Key Properties and Typical Applications of Glass Materials

Understanding the properties of glass materials helps identify which one is best suited for a particular glass part or product. Below we outline some of the key properties and typical applications of our glass material offerings.

- Borosilicate Glass. Borosilicate glass exhibits exceptional chemical resistance, which makes it ideal for use in scientific and medical facilities.

- Fused Silica Glass. Fused silica has a high fusion temperature (1650° C), which enables it to withstand temperatures up to 1400° C for short periods of time. While this quality makes it difficult and expensive to fabricate, it makes the material well-suited for aerospace and other critical applications involving high temperatures. The material is also suitable for applications that require high-purity glass components that have minimal thermal expansion tendencies.

- Gauge Glass. Gauge glass is a transparent tube that allows industry professionals to measure liquid levels in boilers, tanks, and other similar equipment.

- Low-Iron Glass. Low-iron glass is characterized by low coloration and high optical transmission. It is used in applications that require these characteristics and/or where aesthetic quality is critical.

- Quartz Glass. Quartz glass has high purity levels, exhibits excellent temperature resistance, and accommodates precise dimensional tolerances. These qualities, among others, make it suitable for use in lenses, mirrors, optical components, and metrology equipment parts.

- Soda Lime Glass. Soda lime glass is often used for window panes, glass containers, and food and beverage industry components.

Glass Fabrication Capabilities at Swift Glass

Over the years, we’ve expanded our glass fabrication capabilities to meet the changing needs of our customers. Our current service offerings include:

- Waterjet Cutting. We utilize two-axis and three-axis CNC waterjet cutters to cut various glass materials into a wide range of shapes and sizes with ±.01 inch tolerances.

- CNC Machining. Our three-axis and four-axis CNC machines allow us to process glass materials in sizes up to 27 inches (width) by 48 inches (length) by 8 inches (thickness).

- Glass Drilling. We utilize diamond-tipped drill bits to cut through glass materials up to .75 inches in thickness with ±.01 inch tolerances.

- Edge Grinding and Polishing. Our state-of-the-art grinding and polishing equipment allow us to achieve parallel and perpendicular tolerances of .0005 inches on various glass materials.

- Thermal Glass Tempering. We offer glass tempering for glass materials up to 34 inches wide by 72 inches long (up to 1-inch thicknesses) and 14 inches by 14 inches (in 1-inch to 2.375-inch thicknesses)

- Chemical Glass Strengthening. We chemically strengthen glass materials up to 30 inches wide by 40 inches long.

- Surface Lapping and Polishing.We provide manual and CNC lapping and polishing services for small components (single-sided operations) and precision optical parts (double-sided operations). We also apply anti-reflective and surface mirror coatings upon customer request.

- Glass Wafer Fabrication We create glass wafers from borosilicate and quartz for biotechnology, integrated circuit packaging, MEMS, semiconductor, and other industrial applications.

- Corning Gorilla Glass Fabrication. We are a proud fabricator of Corning® Gorilla® Glass. We offer cutting, edge grinding, and other fabrication capabilities to customize this specialty material to suit various applications.

- Inspection. Regardless of project size, we subject our fabricated parts to rigorous quality control processes—including first-piece inspection, random sampling, and final checks—to ensure they meet customer specifications and standards.

- Clean Room Operations. We use an ISO Class 7 clean room to fabricate glass components for optical, semiconductor, and other sensitive applications.

Benefits of Partnering With an All-In-One Glass Fabrication Company

Throughout our nearly 100 years in business, we’ve developed a reputation for excellent products and services. We are an all-in-one glass fabricator, which means we can complete glass fabrication projects without contracting operations to third-party vendors. By partnering with us for their glass parts needs, our customers benefit from the following:

- Shorter Turnaround Time. By keeping raw glass material in stock and maintaining a complete fleet of manufacturing and finishing equipment, we make it fast and easy for our team to fulfill glass fabrication requests. If needed, we can also offer expedited lead times at an additional cost for projects with tight timelines.

- Lower Production Costs. By keeping fabrication operations in-house, we’re able to optimize production to eliminate unnecessary costs. As such, we can provide customers with budget-conscious glass fabrication solutions.

- Better Product Quality. Our comprehensive quality control protocols and sophisticated inspection and testing equipment ensure our fabricated glass parts and products fully meet and/or exceed customer expectations.

Contact the Glass Fabrication Experts at Swift Glass Today

Based in Elmira, NY, Swift Glass is a leading glass part fabrication partner for customers across the globe. To learn more about our glass fabrication capabilities or discuss your project requirements with one of our experts, contact us today.